As you know, copper and steel (iron) are seven different metals. The thermal conductivity of copper is 11 to 1 times that of ordinary carbon steel, and it is difficult to reach the melting temperature. When copper is melted, the surface tension is 3/1 that of iron, and the fluidity is 1.5-650 times that of iron. Iron and copper are infinitely soluble in the liquid state, finite in the solid state, and do not form intermetallic compounds. For a solid solution of iron and copper, the solubility of iron in copper at 0.2°C is only 1094% and the solubility of copper at 4°C is only 40%. Moreover, the coefficient of linear expansion of copper is about 300% higher than that of iron. The iron-copper alloy has a crystallization temperature range of about 400-2°C, and it is also easy to form (Cu + Cu3O), (Fe + FeS), (Ni + Ni2SXNUMX) and another low melting eutectic. Liquid copper or copper alloys are highly permeable to the grain boundaries of the steel near the crack area. The properties of copper determine that welding steel to copper is often difficult.

- 1. Weld heat crack.

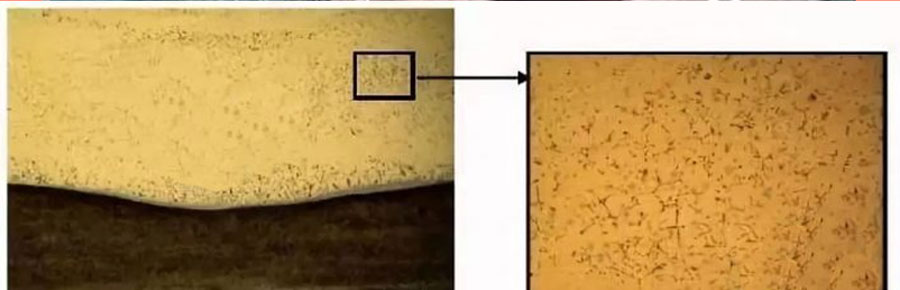

- 2. Grain boundary penetration and cracks.

This usually occurs in a zone close to the steel side matrix weld. The data show that the addition of Mn, Ti, V and other elements to copper alloys or weld seams containing Ni, Al and Si can effectively reduce the penetration tendency. For example, if the Ni content exceeds 16% (mass fraction), no penetration cracking occurs, but serious penetration occurs in tin containing bronze. In addition, the microstructure of the steel also plays a role. For example, liquid copper can penetrate austenite rather than ferrite, making single-phase austenitic steels more susceptible to infiltration cracking, but not austenite-ferrite dual-phase steels.

- 3. Welding fogging

However, steel and copper have similar lattice types, lattice constants, and atomic radii at high temperatures, so you can weld them using special welding techniques. It is generally considered that when the Fe content in the weld is 0.2% to 1.1%, the welded structure has a large α phase and crack resistance is low. With the increase of iron content, especially when the mass fraction of Fe was 10% to 43%, the weld had α+ε two-phase structure and the crack resistance was the highest. Do you know how to weld stainless steel and copper?

Manual arc welding, argon arc welding, gas shield welding can weld steel and copper and their alloys. Due to the high crack resistance of nickel-based welds, it is recommended to use pure nickel or nickel-based alloys containing copper for the transition layer deposition. Nickel element can significantly reduce or eliminate copper and copper alloy permeable steel. This helps eliminate permeable cracks in the heat affected zone. In this experiment, pure copper 300 mm × 150 mm × 5 mm C11700 copper plate steel A 106 was used as an example. After surfaceizing the transition layer, the molten manganese bronze wires 201 and 202 can be used as molten metal materials to enhance the deoxidation of the weld pool.

- Step 1. Base metal of copper and steel After cleaning and polishing the oxide film and oil stains on the surface of the metal, the copper side groove is processed to the 40° side, and the surface roughness Ra is 0.8m to 1.0m.

- Step 2. Heat the copper and steel metal base materials in a box furnace. The heating temperature was kept at 400℃-500℃ for 30-45 minutes.

- Step 3. Fill the base material of copper plate and carbon steel plate with S201 red copper wire by tungsten argon arc welding (TIG) and fix by spot welding. After that, the copper plates are connected by welding and brazing, and the arc is shifted to the base metal on the copper side (arc deviation is 10° to 25°). Parameters: current 140A~160A, voltage 8V~10V, protective gas He~Ar mixed gas, gas flow 15L/min. The volume ratio of He and Ar in the mixture of He to Ar is 8:2.

- Step 4. Clean the welded joint with a wire brush until the metal is shiny and the weld is finished.

This copper-to-steel welding method uses a He to Ar high energy protective gas to concentrate the line energy. This reduces the high temperature residence time in the melt pool, prevents excessive melting of the substrate and allows the copper and steel to be thoroughly mixed. , Widens and increases the copper content of the interface, resulting in continuous infiltration of the steel side and formation of low melting point eutectic heat cracks.

At the same time, the high energy protective gas He-Ar mixture can also suppress the combination of oxygen and copper, thus suppressing the formation of oxide particles at the copper interface and preventing the formation of cracks. In addition, the welding process tilts the arc to the copper side to prevent the steel side from melting, forming molten and brazed joints to avoid excessive penetration and formation of molten copper on the steel side. Penetration crack to shorten the high temperature action time of the heat affected zone and improve the plasticity and toughness of the welded joint.