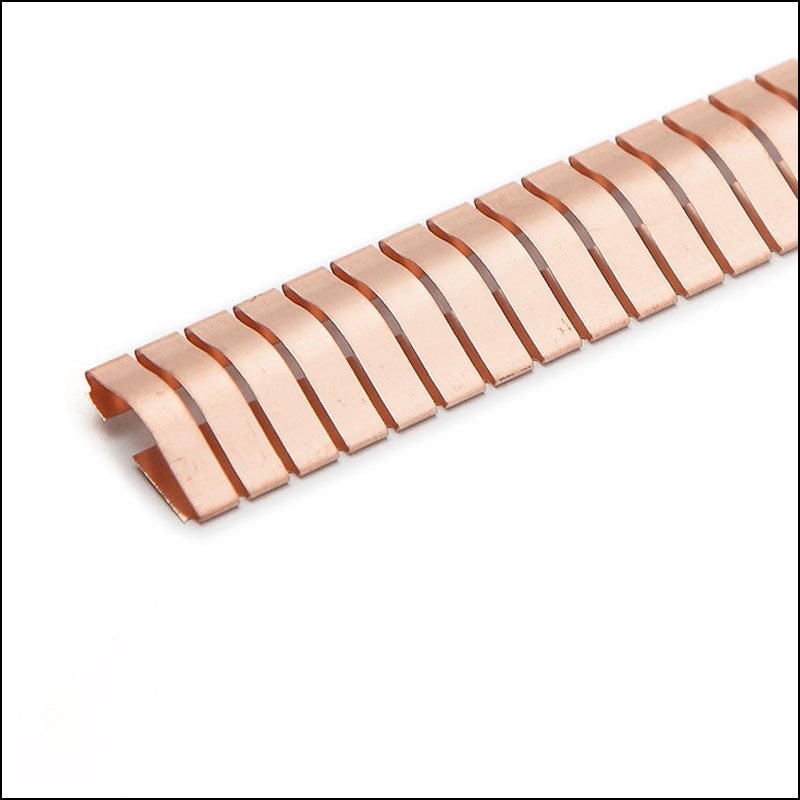

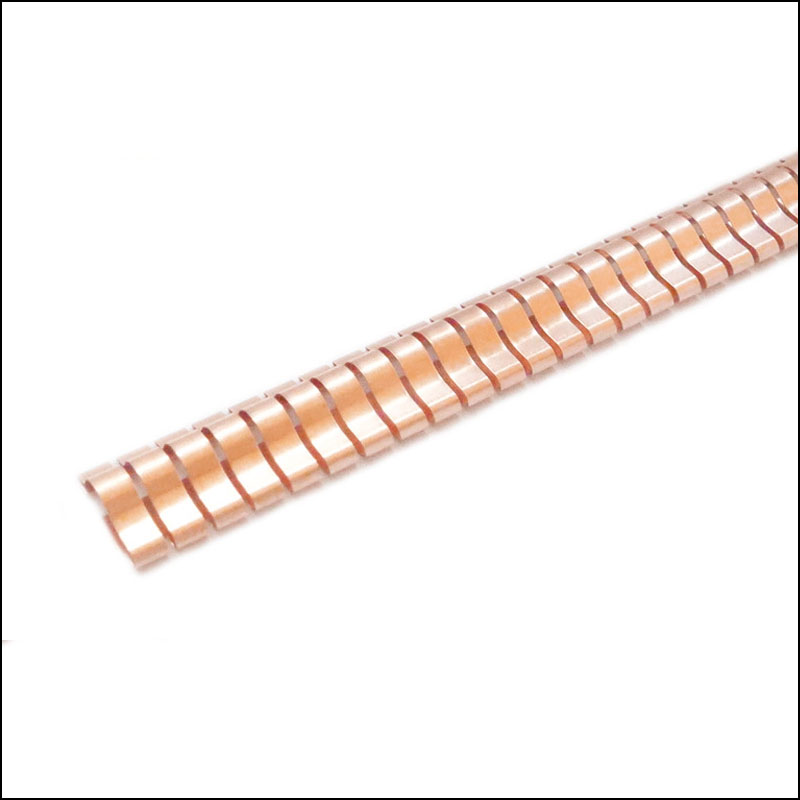

Beryllium Copper EMI Shielding Material / EMI Finger Stock

BeCu Fingerstock is made of beryllium copper alloy reed with electromagnetic compatibility shielding effect. It can be used to seal the gap between two contact surfaces and provide high shielding effect. BeCu Fingerstock can also choose stainless steel and phosphor bronze to meet customer needs. BeCu Fingerstock has a high degree of relaxation resistance and excellent wear resistance. A variety of metal plating treatments can be used to ensure its compatibility with any contact surface. It will not burn, nor will it be affected by radiation. With these advantages, design engineers of computers and electrical appliances regard BeCu Fingerstock as an ideal electromagnetic compatibility shielding material.

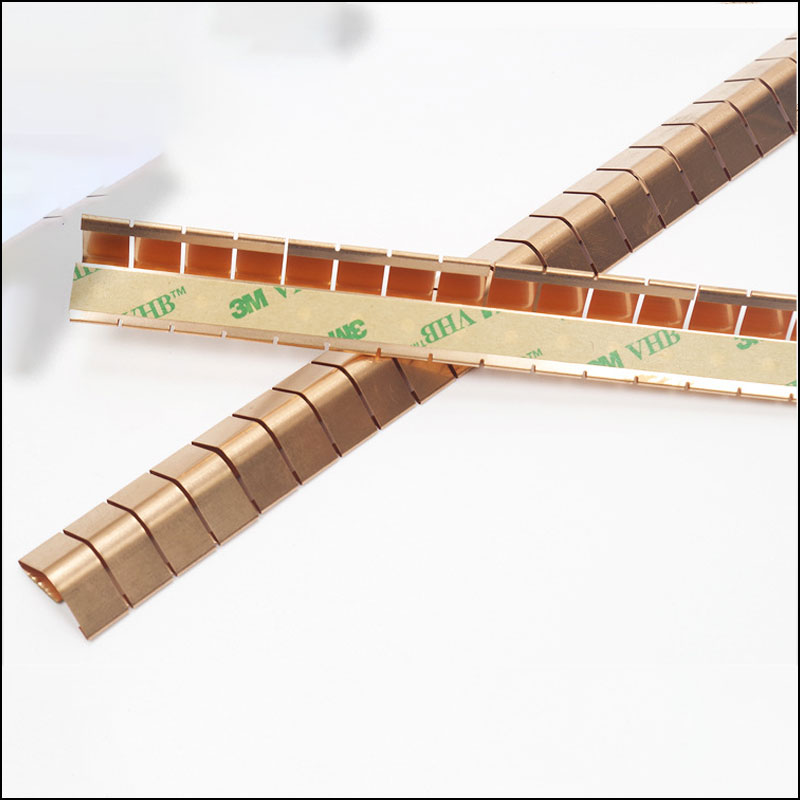

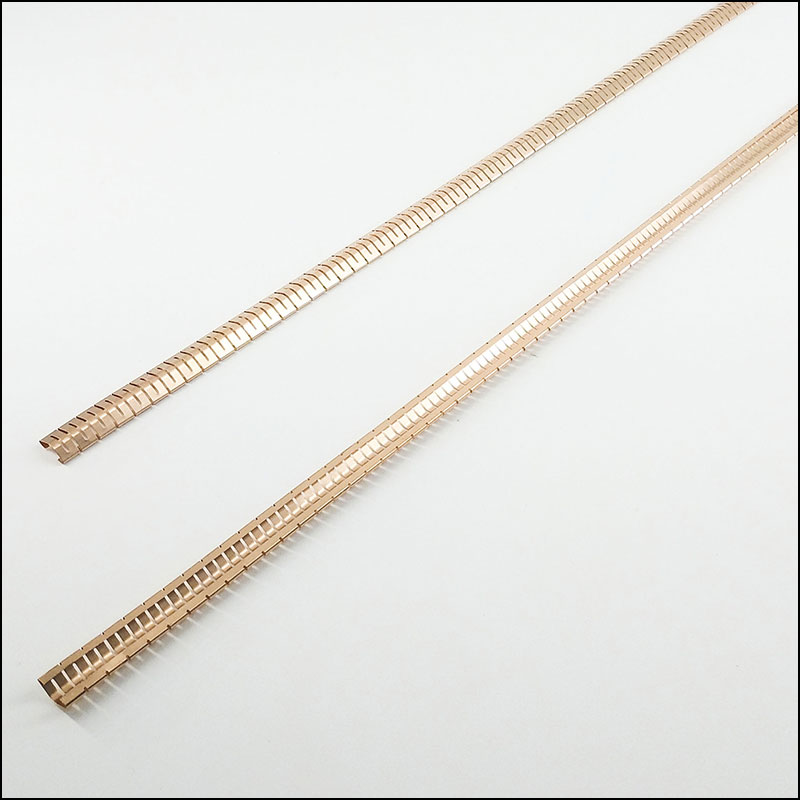

BeCu Fingerstock has excellent compression resistance, resilience, and corrosion resistance, and provides a good broadband electromagnetic shielding effect, especially suitable for communication cabinets and computers, shielding rooms/doors, panels, gaps between plugs filling. The installation methods of beryllium copper reeds are flexible and diverse, generally including paste type, hook type, groove type, guide rail type and screw fastening type. The BeCu Fingerstock gasket is the one with the widest application frequency, the highest shielding effectiveness, the largest compressible deformation range, and the best anti-aging and anti-fatigue performance among all conductive gaskets. Compared with metal spiral tube gaskets, BeCu Fingerstock gaskets can be compressed and deformed up to 20%~80%; for easy installation, BeCu Fingerstock installation forms include bonding, crimping and riveting; at the same time, because the material is generally Beryllium bronze has strong resistance to electrochemical corrosion, so its application range is obviously larger than that of metal spiral tube gaskets.

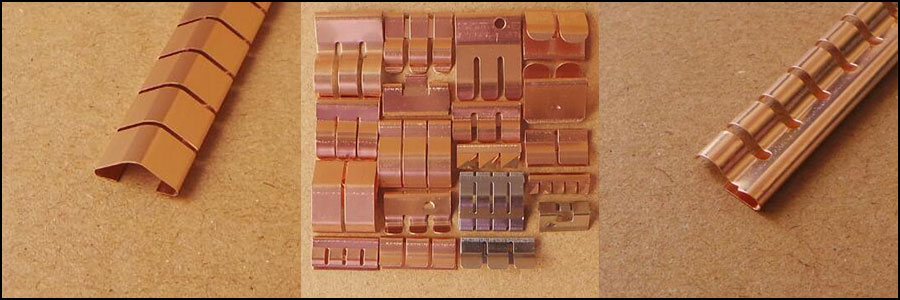

- 1.Slot Mount、Adhesive Mount Series

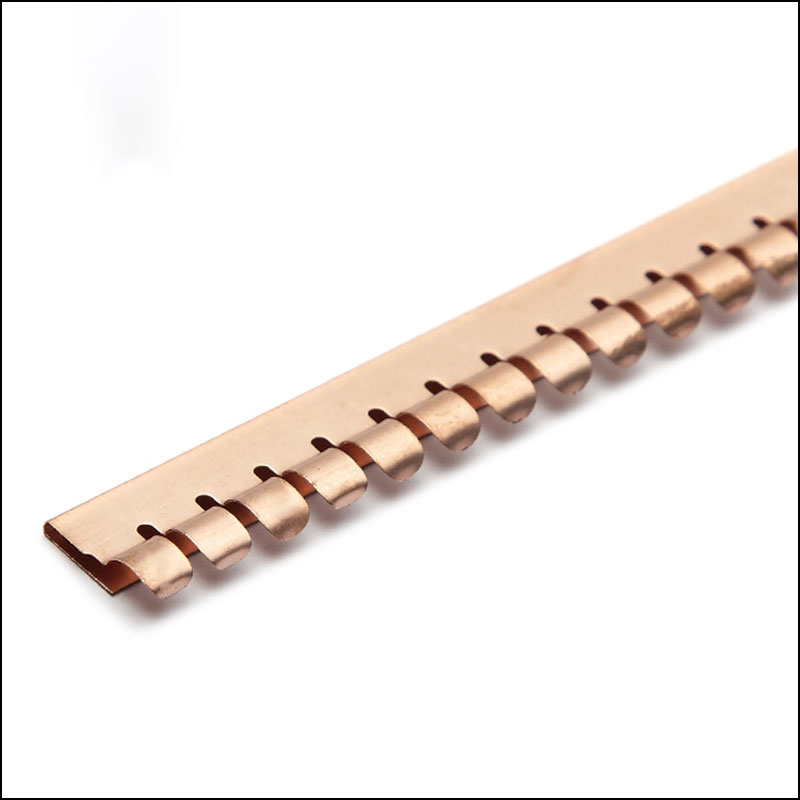

- 2.Dome Top Series

- 3.Folded Series

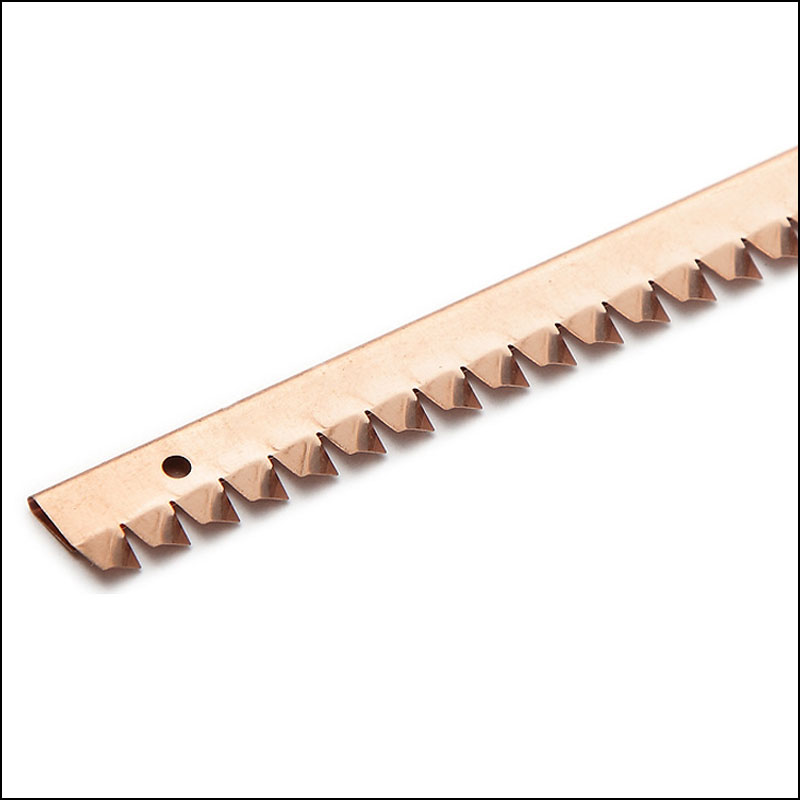

- 4.Twist Series、Clip-On Series

- 5.Contact Series

EMI metal shielding products are suitable for a wide range of electronic equipment with EMI / RFI or ESD problems. There are many different shapes and sizes of products to choose from.

Metal shielding products will not burn, and will not be affected by rays, ultraviolet rays or ozone. It not only solves the problem that other gasket materials cannot withstand tangential sliding contact, but also has excellent shielding performance in a wide frequency range. Good elasticity, so it has excellent reusability. Good mechanical properties, suitable for multiple purposes. Metal shielding products can work well in a variety of environments (such as high temperatures), and there are a variety of coatings to choose from to ensure compatibility with other contact surfaces. The joining pressure is small, the weight is light, and the installation methods are flexible and diverse. And has the characteristics of high thermal conductivity, good pressure resistance, good wear resistance and good plasticity. Therefore, excellent designers use metal shielding products as ideal EMI shielding materials in communication equipment, computers, portable electronic equipment, medical equipment, and military instruments.

There are many types and various installation methods, which can be used in various shielding rooms/cabin doors/chassis doors/covers/printed boards/integrated circuit shielding, etc. It can be better applied to occasions where the shielding material needs to be placed on the top or side of the shielding body, so there is sliding friction. Suitable for various occasions from small handheld devices to large shielded rooms.

- 1) Good conductivity, high tensile elasticity, high shielding effect, good corrosion resistance, long service life, easy installation;

- 2) High cost-effectiveness, multiple electroplating options, good performance at high temperature, humidity and ultraviolet rays;

- 3) The material is high beryllium copper, which has the best elasticity and conductivity. 12. It occupies a small area of the PCB and replaces labor with SMT;

- 4) Special exterior design, in addition to excellent electrical conductivity, it also has a good effect on EMI, ESD or signal transmission;

- 5) Large contact surface, good EMI effect, easy welding, and good product reliability.

Beryllium Copper - the ideal shielding material

Beryllium Copper Unique Material Properties

Beryllium Copper EMI Shielding Gasket / EMI Finger Stock Available products:

- C17200 beryllium copper EMI Spring Leaf

- Finger stock

- C17200 beryllium copper stampings

- other EMI Shielding components and stamping parts

Beryllium Copper EMI Shielding Gasket / EMI Finger Stock Typical application:

- Mobile phone

- Apparatus

- Instruments Meters

- Radio

- Medical Equipment

- Multimeter And Home Appliances

- Stamping Parts

- Circuit Boards

- Electronic Enclosures

- Punching Parts

- Brush Spring

- Electrical Brush

- Plate Spring

- Switch Contact

- Contact Pin

- Gear Box

- Plate Cover

- Interconnect Cables.

EMI Finger Stock Case Studies

Excellent Properties Of Beryllium Copper Alloy

Chemical Composition

Mechanical properties and conductivity analysis

Available status

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).