In the realm of manufacturing, molds play an indispensable role in shaping products across a myriad of industries. The choice of mold material significantly impacts the quality, cost, and efficiency of the manufacturing process. Two prominent contenders in the mold material arena are beryllium copper and tungsten steel. This article delves deep into the nuances of these materials, comparing their properties, applications, advantages, and disadvantages, aiming to provide manufacturers and engineers with valuable insights for making informed decisions.

Beryllium Copper Molds

Properties and Composition

Beryllium copper molds are characterized by their remarkable combination of mechanical and thermal properties. They are an alloy of copper and beryllium, often with a small addition of other elements such as nickel or cobalt. Beryllium copper’s defining features include high strength, good electrical and thermal conductivity, corrosion resistance, and an impressive ability to withstand wear and fatigue.

Applications

- Plastic Injection Molding: Beryllium copper molds are often utilized in plastic injection molding due to their excellent thermal conductivity. This property ensures uniform cooling and faster cycle times, resulting in high-quality finished products.

- Die Casting: Die casting involves subjecting molten metal to high pressures to create intricate shapes. Beryllium copper molds are preferred for die casting due to their thermal conductivity, which helps maintain consistent cooling rates and minimizes defects.

- Electronics Industry: The combination of good electrical conductivity and thermal resistance makes beryllium copper an ideal material for manufacturing electronic components, connectors, and switches.

Advantages of Beryllium Copper Molds

- Thermal Conductivity: Beryllium copper’s exceptional thermal conductivity allows for rapid heat transfer during the molding process, reducing cycle times and improving efficiency.

- High Hardness: The alloy’s hardness and wear resistance contribute to prolonged mold life and consistent product quality.

- Corrosion Resistance: Beryllium copper’s resistance to corrosion ensures that molds remain functional even in harsh environments.

- Dimensional Stability: Beryllium copper’s low coefficient of thermal expansion helps maintain the mold’s dimensional accuracy over multiple molding cycles.

Disadvantages of Beryllium Copper Molds

- Cost: Beryllium copper is relatively expensive compared to other mold materials, which can impact the overall cost of manufacturing.

- Toxicity Concerns: Beryllium is a toxic element, and proper safety measures must be taken during manufacturing and maintenance to prevent exposure.

- Limited Availability: Beryllium copper is not as widely available as other mold materials, potentially leading to supply chain challenges.

Tungsten Steel Molds

Properties and Composition

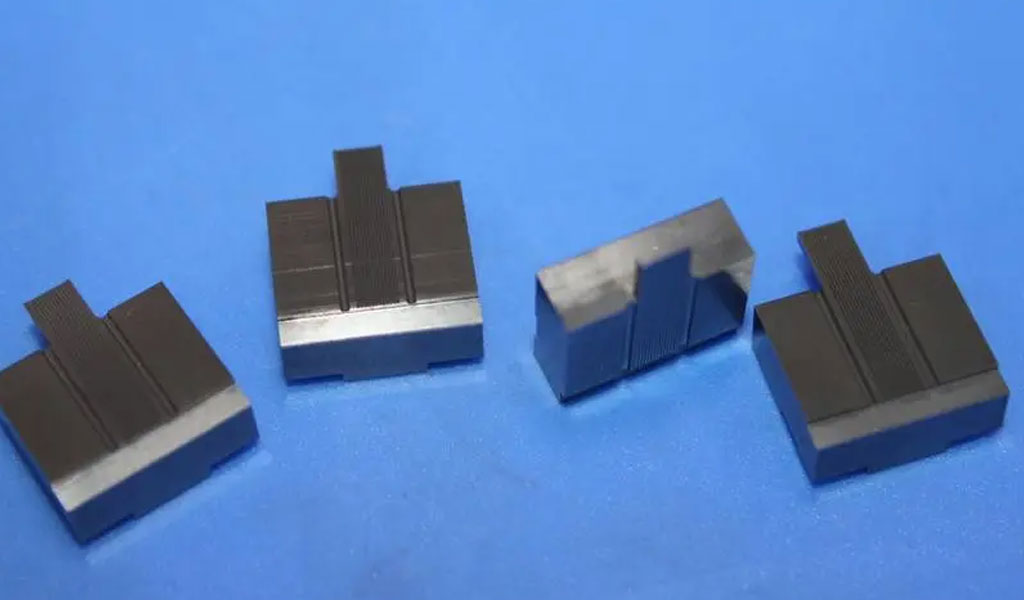

Tungsten steel, also known as tungsten carbide, is a composite material composed of tungsten and carbon atoms. It is renowned for its exceptional hardness, wear resistance, and high melting point. Tungsten steel molds are often alloyed with cobalt to improve toughness and reduce brittleness.

Applications

- Metal Stamping and Forming: Tungsten steel molds are extensively used in metal stamping and forming processes due to their remarkable hardness and resistance to deformation.

- Glass and Ceramic Production: The ability of tungsten steel molds to withstand high temperatures and abrasion makes them suitable for shaping glass and ceramic products.

- Powder Metallurgy: Tungsten steel molds play a critical role in powder metallurgy processes where powdered metals are compacted and sintered to form solid components.

Advantages of Tungsten Steel Molds

- Extreme Hardness: Tungsten steel’s exceptional hardness ensures minimal wear and deformation during prolonged use, leading to longer mold lifetimes.

- Temperature Resistance: Tungsten steel’s high melting point allows it to withstand elevated temperatures without compromising its structural integrity.

- Wear Resistance: Tungsten steel’s resistance to abrasion makes it ideal for applications involving high levels of friction and wear.

- Wide Range of Applications: Tungsten steel molds find utility in diverse industries, from automotive to aerospace, due to their versatility and durability.

Disadvantages of Tungsten Steel Molds

- Brittleness: Despite its hardness, tungsten steel can be brittle, which might lead to cracking or chipping under certain conditions.

- Complex Machining: Tungsten steel’s hardness makes it challenging to machine and fabricate, potentially increasing manufacturing costs.

- Thermal Conductivity: Tungsten steel’s lower thermal conductivity compared to beryllium copper might result in uneven cooling during the molding process.

Comparative Analysis

- Mechanical Properties: Beryllium copper boasts higher thermal conductivity and better electrical conductivity than tungsten steel. Tungsten steel, on the other hand, outperforms in terms of hardness and wear resistance.

- Thermal Conductivity: Beryllium copper has superior thermal conductivity, ensuring efficient heat transfer and uniform cooling. Tungsten steel lags behind in this aspect.

- Applications: While both materials have their dedicated applications, beryllium copper molds excel in plastic injection molding and die casting, whereas tungsten steel finds prominence in metal stamping and high-temperature processes.

- Cost Considerations: Beryllium copper is more expensive upfront, but its faster cycle times and extended mold life can offset this cost over the long term. Tungsten steel might have lower initial costs but could entail higher maintenance expenses.

- Toxicity and Safety: Beryllium copper carries toxicity concerns due to its beryllium content. Tungsten steel is not toxic but can pose challenges during machining due to the potential release of tungsten dust.

Conclusion

Choosing between beryllium copper and machining tungsten steel molds involves a careful evaluation of the specific needs and constraints of each manufacturing process. Beryllium copper’s excellent thermal conductivity and corrosion resistance make it a prime choice for molding processes requiring rapid and consistent cooling. On the other hand, tungsten steel’s remarkable hardness and wear resistance render it indispensable for applications subject to high friction and wear. Ultimately, manufacturers must weigh factors such as material cost, mold longevity, efficiency gains, and safety considerations to make an informed decision that aligns with their production goals and requirements.