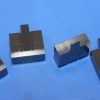

Beryllium copper molds are widely used in various industries for their exceptional mechanical properties, thermal conductivity, and resistance to wear and corrosion. These molds find applications in plastic injection molding, die casting, and other manufacturing processes. In this article, we will delve into the step-by-step process of making beryllium copper molds, focusing on safety precautions, materials, design considerations, and the manufacturing process. Let’s explore the art of crafting these molds to ensure precision and efficiency in the manufacturing process.

Safety Precautions

Before diving into the mold-making process, it is crucial to understand the safety considerations associated with working with beryllium copper. This material contains beryllium, which can be hazardous if inhaled in the form of dust or fumes. Ensure that you are in a well-ventilated area, wear appropriate personal protective equipment (PPE) such as masks and gloves, and strictly adhere to safety guidelines while handling beryllium copper.

Material Selection

Beryllium Copper Alloys

Beryllium copper molds are typically made from copper alloys containing a small percentage of beryllium (usually 0.5% to 2.7%). These alloys are classified into two types: age-hardened and mill-hardened. Learn about the different alloy compositions and choose the one that best suits your specific mold-making requirements.

Tool Steel Inserts

To enhance the mold’s durability and lifespan, tool steel inserts can be incorporated into the beryllium copper mold. Understand the benefits of using tool steel inserts and the different types available, including H13, P20, and stainless steel.

Design Considerations

Mold Design

Proper mold design is vital for achieving the desired product quality and manufacturing efficiency. Discuss the essential aspects of mold design, such as gating systems, cooling channels, ejection mechanisms, and venting.

Draft Angles

Draft angles play a crucial role in ensuring smooth ejection of the molded parts. Explore the significance of draft angles and guidelines for their appropriate application in beryllium copper molds.

Surface Finish

Surface finish impacts the final product’s aesthetics and functionality. Delve into the methods and techniques used to achieve the desired surface finish in beryllium copper molds.

Mold Manufacturing Process

Mold Fabrication

Explain the different techniques used for fabricating beryllium copper molds, including CNC machining, EDM (Electrical Discharge Machining), and additive manufacturing processes like DMLS (Direct Metal Laser Sintering).

Wonder Group, your premier destination for precision beryllium copper machining solutions. With a reputation for excellence and an unwavering commitment to customer satisfaction, we are a leading company specializing in the china cnc machining manufacturer of beryllium copper components for diverse industries. Backed by a team of highly skilled engineers, state-of-the-art technology, and years of experience, we pride ourselves on delivering top-notch machining services that meet the most stringent quality standards. Whether you require custom-designed beryllium copper molds, complex parts, or prototypes, we have the expertise and resources to bring your visions to life with precision, efficiency, and unmatched craftsmanship. At Wonder, we take every project as an opportunity to exceed expectations and build lasting partnerships with our valued clients. Experience the epitome of beryllium copper machining excellence – choose [Company Name] for all your precision engineering needs.

Heat Treatment

The heat treatment process is critical for age-hardened beryllium copper alloys. Describe the heat treatment process and its effects on the mechanical properties of the mold.

Polishing and Finishing

After the mold fabrication, a series of polishing and finishing steps are essential to achieve the desired surface quality. Discuss the various polishing techniques used in beryllium copper molds.

Maintenance and Care

Cleaning and Inspection

Proper maintenance and care are vital to ensure the longevity and optimal performance of beryllium copper molds. Elaborate on the cleaning and inspection procedures to keep the molds in top condition.

Repairs and Refurbishment

Discuss common issues that may arise during the mold’s lifetime and the steps to repair and refurbish the molds, including welding and re-machining processes.

Crafting beryllium copper molds is a meticulous process that requires careful consideration of safety precautions, material selection, design aspects, and the manufacturing process. By following the guidelines presented in this article, manufacturers can create high-quality molds that contribute to enhanced manufacturing efficiency and superior product quality. Remember to prioritize safety at every step, and continuously maintain and care for the molds to ensure their extended lifespan and optimal performance.