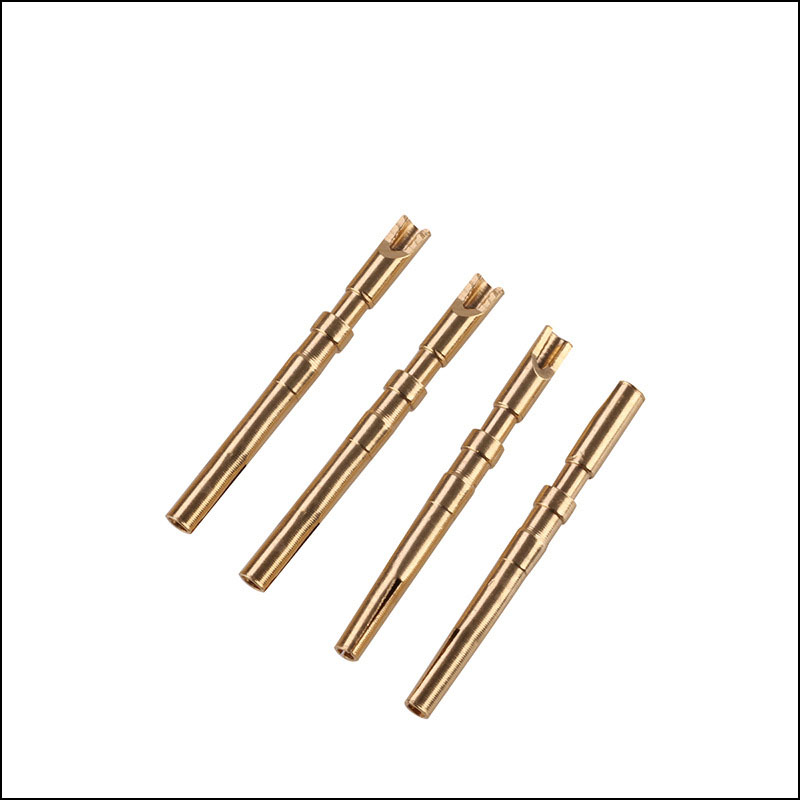

Beryllium Copper Terminal And Pins

Beryllium copper PIN is a metal substance used to complete electrical (signal) conduction (transmission) in connectors. PIN material is “beryllium copper”: beryllium copper has high hardness, strength, wear resistance and corrosion resistance. It is used to manufacture cutting tools, knives, cobalt tools and wear-resistant parts, and is widely used in military, aerospace, With the development of downstream industries in the fields of mechanical processing, metallurgy, oil drilling, mining tools, electronic communications, and construction, the demand for beryllium copper market continues to increase. And in the future, high-tech weapons and equipment manufacturing, advances in cutting-edge science and technology, and the rapid development of nuclear energy will greatly increase the demand for beryllium copper products with high technical content and high quality stability.

The basic forms of pins are cylindrical pins and tapered pins. The cylindrical pin is fixed in the pin hole with a small amount of interference. Multiple assembly and disassembly will reduce positioning accuracy. The taper pin has a taper of 1:50 and can be self-locking. It is fixed in the pin hole by the extrusion of the taper surface. It has high positioning accuracy and is easy to install. It can be assembled and disassembled many times.

The type of pin is selected in use according to its work requirements. The diameter of the connecting pin can be determined by experience according to the structural characteristics of the connection, and the strength should be checked if necessary. The positioning pin can be directly determined by the structure. The length of the pin in each connecting piece is about 1 to 2 times its diameter.

The types of pins are: tapered pins, internally threaded tapered pins, cylindrical pins, internally threaded cylindrical pins, taper pins with open ends, threaded cylindrical pins, elastic cylindrical pins, straight grooves, light-duty, bored pins, taper pins with screw ends, cotter pins, etc.

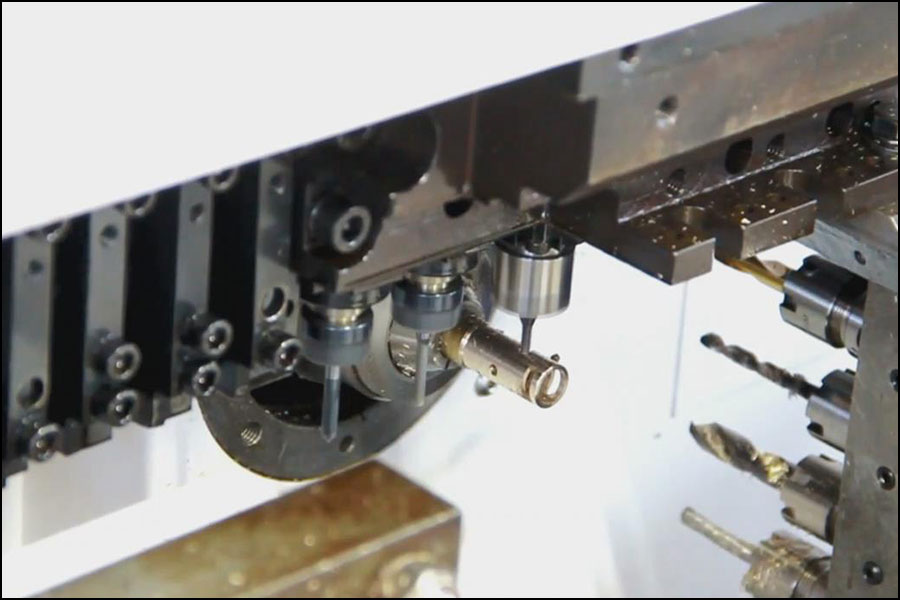

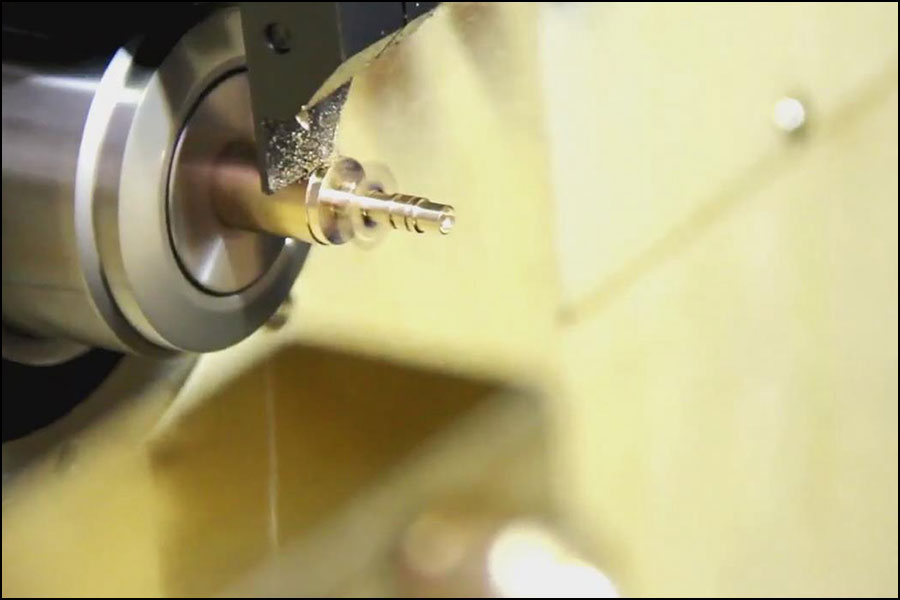

Retractable Terminal And Pins

Terminal And Pins Case Studies

Excellent Properties Of Beryllium Copper Alloy

Chemical Composition

Mechanical properties and conductivity analysis

Available status

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).