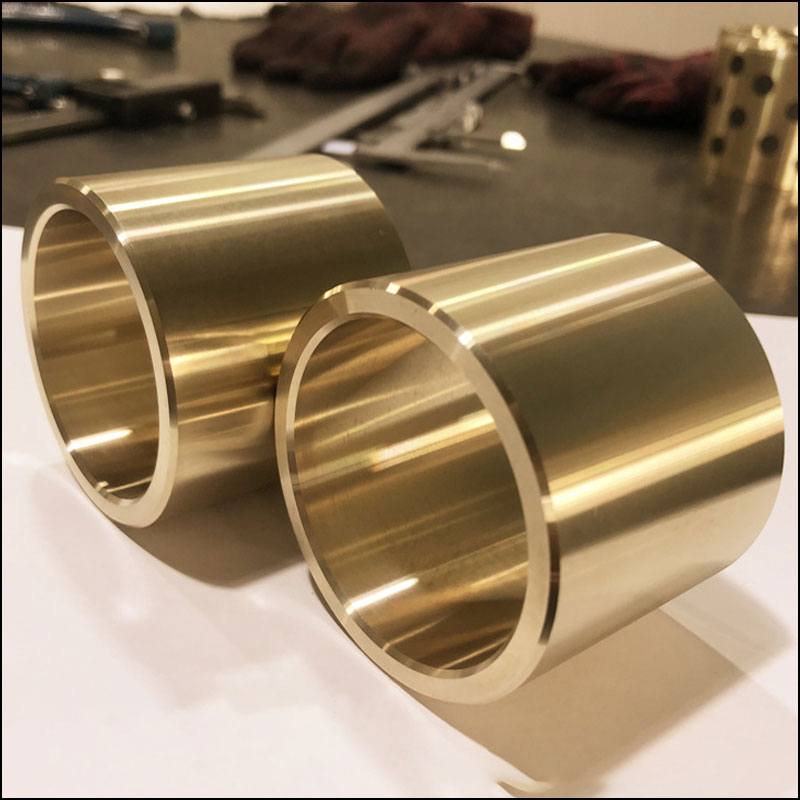

Beryllium Copper Rings/sleeve

Previous

Next

Wonder copper are capable of producing beryllium copper rings according to Customer’s drawing and available samples or detailed inquiry.

Although custom machining & custom beryllium copper rings is highly challenging, customers cannot afford unacceptable delivery delays. Mastering technical challenges while maintaining an uninterrupted reliable supply is an important core competency at Wonder copper. The Wonder copper team of manufacturing professionals knows the distinctive properties of all the beryllium copper alloys in the Stainless category, and adjust the production process to maximize production efficiency.

Beryllium Copper Rings Available products

- C17200 beryllium copper rings

- C17500 beryllium copper ring

- C17510 beryllium copper ring

- CuCo1Ni1Be beryllium copper rings.

Typical application of Beryllium Copper Rings

- Electrical Industry: Instrument parts, connectors, heavy duty relay parts, conductors, switch parts, fuse clips.

- Industrial: Welding equipment parts, die casting plunger tips, high flux electromagnets, thermal transfer plates.

Wonder copper advantage:

- Class 4 Alloy has extremely high hardness and ultimate tensile strength although the electrical conductivity is lower than the Class 3 Alloy

- Class 4 Beryllium Copper (17200) is available in heat treatable tempers. Alloys are used in a wide range of applications requiring high strength and stiffness with good conductivity.

- Typical uses include electrical/electronic connectors, current-carrying springs, precision screw machined parts, welding electrodes, bearings, plastic molds and corrosion resistant components.

- Class 3 copper is specifically recommended for projection welding dies, flash and butt welding dies, current carrying shafts and bushings. Class 3 castings are recommended for welder components that carry current, and are under heavy load, including heavy duty offset electrode holders. Class 3 copper is generally recommended for spot welding and seam welding steels having high electrical resistance, such as stainless steels.

Wonder Copper Rings Case Studies

Excellent Properties Of Beryllium Copper Alloy

High Flexibility

High Hardness

High Strength

High Conductivity

High Thermal Conductivity

Good Molding Properties

Good Fatigue Performance

Excellent Corrosion Resistance

No Spark Impact

Chemical Composition

Executive standard:ASTM/GB/T5233-2001/EN12163(%max., unless shown as range or min.)

Numbering

Be

Co+Ni

Cu

Fe

Pb

Si

Al

C17200

1.8-2.0

Co+Ni≥0.2

Margin

0.15

-

0.15

0.15

C17300

1.8-2.0

Co+Ni≥0.2

Margin

0.15

0.2-0.6

0.15

0.15

C17500

0.4-0.7

Co 2.4-2.7

Margin

0.15

-

0.15

0.15

C17510

0.2-0.6

Co≤0.3,Ni 1.4-2.2

Margin

0.15

-

0.15

0.15

QBe2.0

1.8-2.1

Ni 0.2-0.5

Margin

0.15

0.005

0.15

0.15

BeCo1Ni1

0.4-0.7

Co 0.8-1.3,Ni 0.8-1.3

Margin

0.02

-

0.02

0.04

Mechanical properties and conductivity analysis

(AT/TF00)

Numbering

Tensile Strength /MPa

Yield Strength /MPa

Elongation %

Hardness

Conductivity %IACS

C17200

1160-1380

980-1240

3—15

36-42HRC

22-28

C17300

1160-1380

980-1240

3—15

36-42HRC

22-28

C17500

700-920

560-710

10—25

92-100HRB

45-60

C17510

700-920

560-710

10—25

92-100HRB

45-60

QBe2.0

1160-1380

980-1240

3—15

36-42HRC

18-20

BeCo1Ni1

700-920

560-710

10—25

92-100HRB

45-60

Available status

Brush Name

ASTM Name

Description

A

TB00

Solution annealing state (quenched state)

¼H

TD01

Quarter hard

½H

TD02

Half hard (semi-hard)

¾H

TD03

Three-quarters hard

H

TD04

Hard state (full hard)

AT

TF00

Standard aging heat treatment in quenched state

¼HT

TH01

Quarter hard standard aging heat treatment

½HT

TH02

Half-hard standard aging heat treatment

¾HT

TH03

Three-quarters hard standard aging heat treatment

HT

TH04

Hard standard aging heat treatment (a process of comprehensive strengthening of deformation and aging)

Note: In the Brush name:

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).