The Application Of Beryllium Copper In Electric vehicle Charger

September 2, 2020

342 Views

SaveSavedRemoved 0

With the improvement of people's living standards, more and more people start to buy cars, but a series of problems such as energy consumption, resource shortage and environmental pollution have been brought about over time. And new energy vehicles came into being and gradually expanded. Among them, the electric vehicle connector plays a role in connecting the nerves and blood vessels of the vehicle. This shows the importance of the connector, so do you know that the connectors are used? Which metal materials? Today we will introduce the application of beryllium copper alloy in electric vehicle chargers.

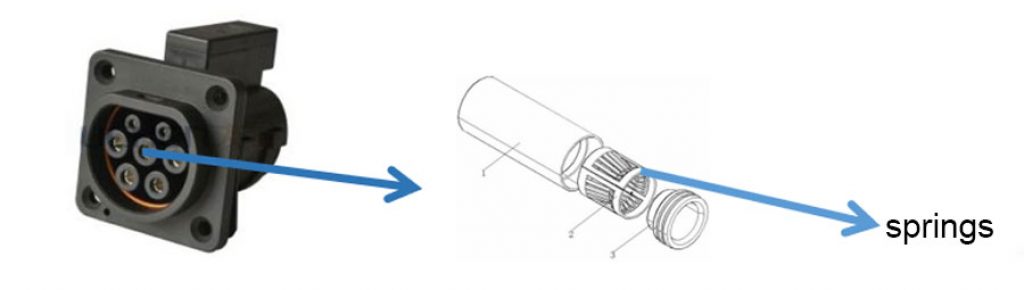

The contact is the core component of the connector to complete the electrical connection. As the core part of the contact, the elastic jack plays a vital role. The crown spring jack is widely used due to its good performance, cost and manufacturing process. When the connectors are plugged and connected to each other, the reed contact area is large, the reliability is high, the contact resistance is small, the intermodulation performance is excellent, it is not easy to be damaged, and can effectively prevent the leakage of electrical signals.

So what kind of material can make the crown spring achieve such superior performance?

The answer is "beryllium copper". Beryllium copper is processed by smelting, casting, hot rolling, and special heat treatment. It has the characteristics of high strength, high elasticity, and non-magnetic properties. It can be called the king of non-ferrous metal elasticity.

Because of its superior performance, beryllium copper is widely used in aerospace, aviation, manufacturing electronic components, electrical parts, resistance welding equipment parts, especially for flexible connectors, thermostat components, and has greater advantages. In the high-tech era Today, its use is more extensive.