The Introduction Of 7 Kinds EMI Electromagnetic Shielding Materials

December 4, 2020

171 Views

SaveSavedRemoved 0

With the rapid development of science and technology and the electronics industry, various digital and high-frequency electronic and electrical equipment radiate a large number of electromagnetic waves of different wavelengths and frequencies to the space when they are working, resulting in new environmental pollution: electromagnetic interference, EMI.

What is EMI

Electromagnetic waves will interact with electronic components and cause interference, which is called EMI (Electromagnetic Interference). For example, the common "snowflakes" on TV screens indicate that the received signal is disturbed.

When electronic devices work, they neither want to be interfered by external electromagnetic waves, nor do they want their own radiated electromagnetic waves to interfere with external devices and harm the human body. This requires electromagnetic shielding to block the propagation path of electromagnetic waves. The electromagnetic attenuation of electromagnetic shielding body is mainly based on the principle of electromagnetic wave reflection and absorption.

Electromagnetic shielding material

According to electromagnetic shielding materials, there are three main categories:

- 1) Metals: directly select metal materials, such as beryllium copper, stainless steel, etc.;

- 2) Filling type: a certain proportion of conductive filler is added to the non-conductive substrate to make the material conductive. The substrate can be made of silica gel, plastic and other materials. The conductive filler can be metal sheet, metal powder, metal fiber or metalized fiber, etc. material;

- 3) Surface coatings and conductive coatings: Electroplating of the substrate. Common preparation methods include electroless gold plating, vacuum spraying, sputtering, metal spraying, and metal foil.

Figure Beki-Shield fiber filler, taken at the Canton Fair booth

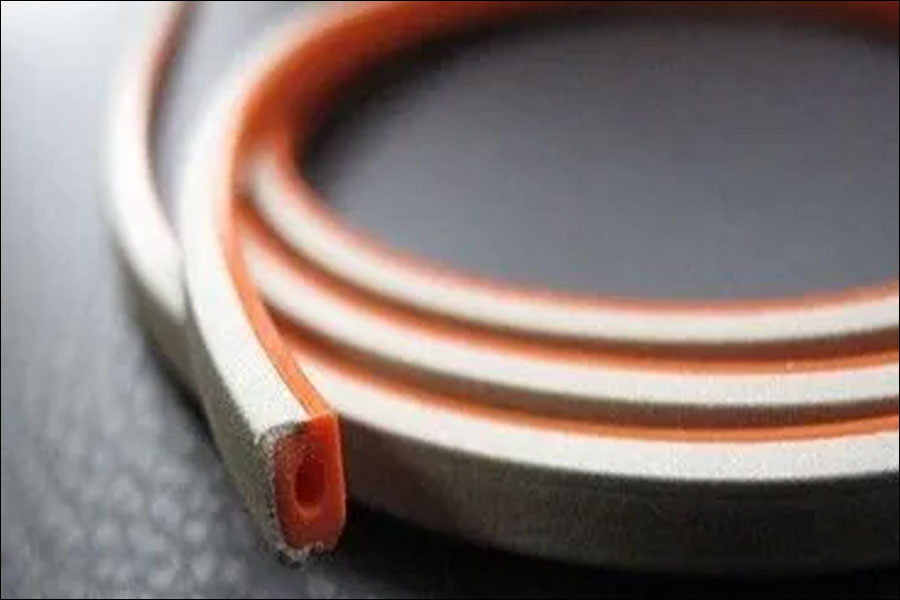

1.Conductive Rubber

Conductive rubber is a rubber material filled with metal fillers, which provides high conductivity, electromagnetic shielding, and moisture-proof sealing. Each conductive rubber is made of silicone, silicone fluoride, EPDM or carbon fluoride-silicon fluoride and other adhesives and pure silver, silver-plated copper, silver-plated aluminum, silver-plated nickel, silver-plated glass, silver-plated It is composed of conductive fillers such as lead or carbon particles.

This material can be shaped into sheet, molded, extruded and film-like shapes as required. Standard shapes are: solid O-shaped strips, hollow O-shaped strips, solid D-shaped strips, hollow D-shaped strips, U-shaped strips, rectangular strips, hollow rectangular strips, hollow P-shaped strips, channel strips, and molded conductive rubber moldings, Molded D-ring/O-ring, various flanges, I/O gasket.

Features and applications: 90 dB-120dB in the range of 20M-20GHz, and even more than 120dB for pure silver particles. Can play the role of shielding and environmental sealing, easy to install. It is applied to parts that require long-term stable excellent electromagnetic shielding and high conductivity. It is widely used in communications equipment, information technology equipment, medical equipment, and industrial electronic equipment markets.

2.Conductive foam (conductive cloth liner)

The conductive cloth liner consists of a conductive layer and a foam core, which can be processed into various shapes. The compressibility and resilience of the foam core can meet the requirements of low sealing force occasions, and it is widely used in the gaps of electronic equipment shells and cabinets. EMI shielding requirements.

Features and applications: With low resistance and high resilience, it can meet multiple opening and closing or plug-in scenarios, and provide stable grounding or shielding performance. Suitable for electromagnetic shielding, anti-static (ESD) and grounding of various electronic equipment. It can be widely used in electronic enclosures, cabinets, indoor enclosures, industrial designs, notebook computers, mobile communication equipment, etc.

Features and applications: 90 dB-120dB in the range of 20M-20GHz, and even more than 120dB for pure silver particles. Can play the role of shielding and environmental sealing, easy to install. It is applied to parts that require long-term stable excellent electromagnetic shielding and high conductivity. It is widely used in communications equipment, information technology equipment, medical equipment, and industrial electronic equipment markets.

3.Conductive cloth

The fiber cloth (commonly used polyester fiber cloth) is pre-treated and then electroplated with metal plating to make it have metallic characteristics and become conductive fiber cloth. Can be divided into: nickel-plated conductive cloth, gold-plated conductive cloth, carbon-plated conductive cloth, aluminum foil fiber composite cloth. The appearance is distinguished by plain weave and grid.

Features and applications: It has good electrical conductivity and shielding effect, good thermal conductivity, good ductility, easy extrusion processing, good corrosion resistance and weather resistance, good friction resistance, and the number of friction resistance can reach 5,000,000 times.

It can be used for professional shielding work clothes for high-radiation work such as electronics and electromagnetics, special shielding cloth for shielding rooms; special cloth for shielding parts in the IT industry, popular touch screen gloves, anti-radiation curtains, etc.

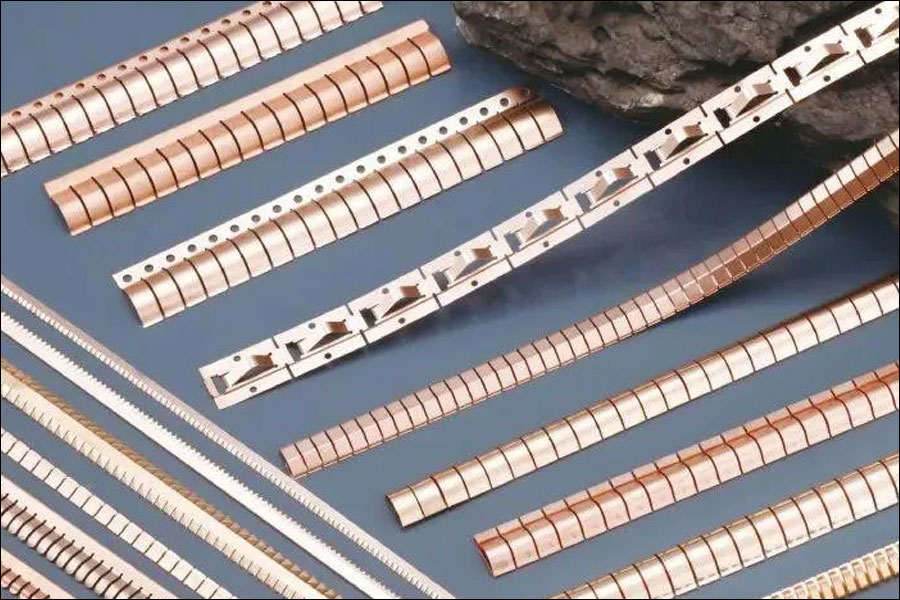

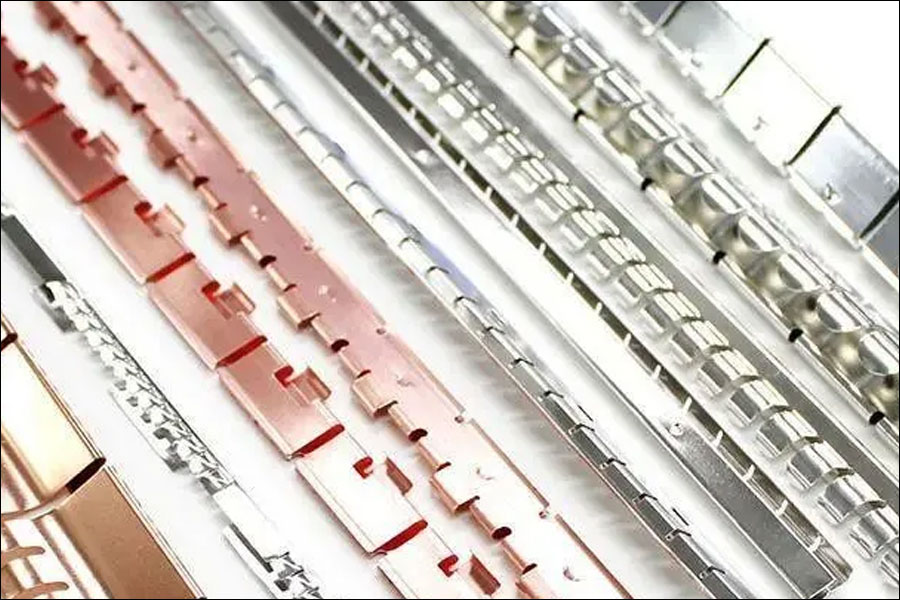

4.Metal EMI lining, clip lining and hook material beryllium copper reed

The clip-on EMI lining is made of carbon-filled silicone strips or Monel wire on silicone tape or Ferrex wire on neoprene to provide EMI shielding. The lining is fixed on a corrosion-resistant stainless steel spring clip for easy installation. No holes or fasteners are required.

Beryllium copper reed is a finger-shaped reed made of special alloy beryllium copper, which combines high-grade EMI shielding effect and elastic hook rubbing with small sealing force characteristics. The high-performance parameters of beryllium copper: high tensile strength, good corrosion resistance and good electrical conductivity, making it an ideal EMI finger shielding material used in a wide frequency band, and can be used in a wide range of electronics with EMI/RFI or ESD problems. In the device.

Application: Widely used in telecommunications, data communications, computers, electronics, network equipment, aerospace, military, automobiles, medical equipment and other fields.

5. Conductive adhesives and conductive coatings

Including conductive adhesives and conductive paints. Conductive adhesives are generally made of metal fillers such as silver particles or silver-plated copper particles that are doped into epoxy resin, silicone, and flexible polyisoethylene through a special process. It has the unique comprehensive properties of high shear strength, small thermal expansion coefficient, pure ions, good thermal and electrical conductivity. Typical applications include bonding EMI shielding channels, windows or light-transmitting conductive screen films to permanent seams of shielding .

Features and applications: Conductive coatings are generally sprayed on various plastic casings such as ABS, Noryl, PVC, etc., which can provide EMI shielding, anti-static protection, corona shielding and surface grounding. Fillers are divided into silver, silver-coated copper, copper, nickel, etc. , The adhesive is usually epoxy resin, polyurethane, etc., and the conductivity can reach 0.015 ohm/sq, which can provide 60-80dB shielding for the chassis in the range of 30MHz-1GHz.

6. STM patch foam

SMT patch foam is a ground terminal that can be used in surface mount technology and is one of surface mount components. For electrical/electronic equipment, in order to avoid malfunction due to unnecessary electromagnetic waves or to reduce the noise of EMI shielding materials, the EMC countermeasure parts can be used by soldering the ground terminal on the PCB.

Features: High-speed surface assembly, suitable electrical conductivity, excellent heat resistance and grounding characteristics, conductive elastic terminals for PCB grounding with excellent durability and reliability, when electrical/electronic equipment is subjected to external impact or drop SMT patch foam has excellent shock absorption characteristics and has the function of protecting internal accessories and cushioning.

7. Absorbing materials

Absorbing materials are generally made by mixing alloy powder with polymer resins through various processes and calendering them into flexible sheet materials, which are converted into heat, potential and other forms of energy through mechanisms such as hysteresis loss, dielectric loss, and resistance loss. To achieve the effect of shielding and absorbing electromagnetic waves.

Application: Absorbing materials are mainly used in communications, electronics, aerospace, military, navigation, medical, environmental protection, and many industrial sectors that use microwave and high frequency. They are widely used in electronic digital products, wireless charging, RFID radio frequency identification, mobile communication equipment, Wireless equipment, office automation equipment (personal computer, TFT LCD, etc.), audio/video communication equipment terminal, digital switch, flexible circuit board, high-speed CPU chip, image processor, oscillator chip, storage chip, high-speed signal line speed, shielding cover Inner shell, high-speed microprocessor, etc.

Upgrading trend of electromagnetic shielding materials

Electromagnetic shielding materials will develop in the direction of higher shielding effectiveness, wider shielding frequency, and better comprehensive performance. The innovative applications of various new materials in electromagnetic shielding will be more developed. In the future technological development, electromagnetic shielding will develop in terms of good electrical conductivity, simple processing technology, high cost performance, and suitable for mass production. In the future, more and more types of electronic equipment will be included in electromagnetic compatibility management standards, and electromagnetic compatibility standards will become more stringent. It is foreseeable that the continuous upgrade trend of electromagnetic device process materials will be a deterministic direction.

Recently, a new shielding technology-conformal shielding has emerged. It is different from the traditional mobile phone EMI shielding method that uses metal shielding covers. The conformal shielding technology is to completely integrate the shielding layer and the package together, and the module itself has Shielding function, after the chip is mounted on the PCB, no additional shielding cover is needed, and no additional equipment space is required. It is mainly used for PA, WiFi/BT, Memory and other SiP module packages to isolate the internal circuit and the external package Interference between systems.

Conformal shielding technology can solve the EMI interference inside SiP and the surrounding environment, and has almost no impact on package size and weight. It has excellent electromagnetic shielding performance and can replace large-size metal shields. It is expected to follow SiP technology and equipment in the future. Popularization for miniaturization needs.