What are beryllium copper and beryllium bronze tubes?

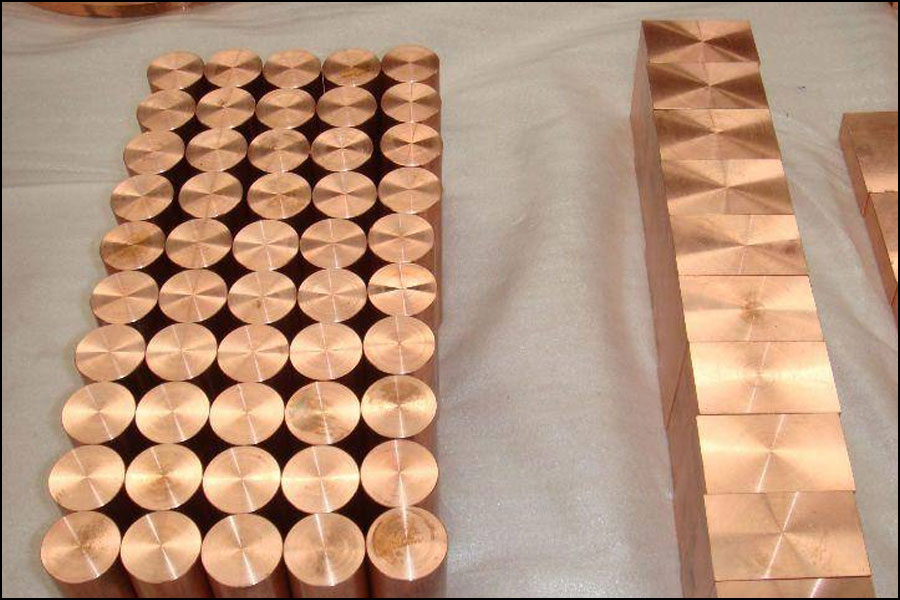

- 1. Beryllium copper is a copper alloy with beryllium as the main alloying element, also known as beryllium bronze. It is a high-grade elastic material with the best performance among copper alloys. It has high strength, elasticity, hardness, fatigue strength, low elastic hysteresis, corrosion resistance, wear resistance, cold resistance, high conductivity, non-magnetic, and no sparks due to impact. A series of excellent physical, chemical and mechanical properties.

- 2. Processing beryllium bronze is mainly used for various high-grade elastic components, especially various components that require good conductivity, corrosion resistance, abrasion resistance, cold resistance, and non-magnetic components. It is widely used as diaphragms, diaphragms, bellows, Micro switches, etc.

- 3. The beryllium copper pipe combines the advantages of metal pipes and non-metal pipes. It is harder than plastic pipes and has the high strength of general metals (the strength of cold drawn copper pipes is equivalent to that of steel pipes with the same wall thickness). It is also more flexible than general metals, has good toughness and high ductility, and has excellent vibration resistance and resistance. Impact and frost heave resistance.

- 4. The beryllium copper tube can withstand extremely cold and extremely hot temperatures, from -196 degrees to 250 degrees, a wide range of applications, and adapt to drastic changes in temperature (-high temperature-low temperature-high temperature -), the performance will not be affected by long-term use and temperature The violent change of the temperature is reduced, and the aging phenomenon will not occur. This is beyond the reach of ordinary pipes.

The preparation method of high-performance large-size beryllium copper pipe is as follows:

- 1. Homogenizing heat treatment, drilling and billeting of the ingot, quenching heat treatment, surface processing, rolling, straightening, aging heat treatment, surface passivation treatment, non-destructive testing, Wall thickness measurement and other processes.

- 2. The beryllium copper pipe produced by this process has high yield and material utilization. The tensile strength of the finally obtained beryllium copper pipe is between 1280 and 1420 MPa, the elongation is between 3% and 5%, and the surface The hardness is between HRC38~42, the grain size is between 7~10μm, which is much higher than the technical indicators of the prior art

- 3. The length of the beryllium copper pipe that can be processed by this technology can reach 4000 mm, and the dimensional accuracy of the inner and outer pipe diameters and pipe wall thickness can reach ±0.2 mm/m.

Explanation of the production quality of beryllium bronze tube

- 1. With the aid of large-scale nonlinear finite element software, two-dimensional axisymmetric elasto-plastic finite element method is used to simulate the stress and strain of beryllium copper pipe in different process drawing processes, and the actual processing quality problems are analyzed.

- 2. Finite element simulation analysis can understand the distribution characteristics of stress and strain during the pipe drawing process, optimizing the die angle can reduce the axial stress and friction, and optimizing the drawing pass can improve the uniformity of the pipe deformation and reduce the residual stress of the pipe, and then Improve product quality, etc.

- 3. The inner and outer surfaces of the beryllium copper pipes actually produced by empty drawing are of poor quality, and the beryllium copper pipes are easy to deform during storage. It is difficult to prepare high-precision beryllium copper pipes by air-drawing technology. The fixed short core head drawing beryllium copper tube overcomes the problems existing in the empty drawing, but it is easy to break and break when drawing, which seriously affects the production.

- 4. The results show that the axial residual stress of the beryllium copper pipe after air drawing is relatively large, the outer surface has high tensile stress, and the inner surface has high compressive stress; while the residual stress of the pipe after the fixed short core head is drawn Smaller.

- 5. The change of equivalent strain and equivalent stress during the drawing process of the beryllium copper tube fixed short core is relatively gentle, and the deformation is more uniform; while the equivalent strain and equivalent stress distribution is uneven after the empty drawing. This shows that the quality and accuracy of the drawn beryllium copper tube with the fixed short core head are relatively high, and the drawing process is more reasonable than the empty drawing process.