Corrosion is one of the important reasons for the surface damage of the car body, especially in the harsh environment such as salt spray, severe cold and damp heat, the car body rust phenomenon is more obvious. Now in the automotive industry, it can be said that rust and discoloration are discussed. In order to solve the problem of corrosion of automobile body-in-white, the most common method for most automobile manufacturers at home and abroad is to use galvanized sheets with good corrosion resistance (including hot-dip galvanized steel sheets and electro-galvanized steel sheets). According to research, the corrosion resistance time of galvanized sheet is 2 to 3 times that of ordinary cold-rolled steel sheet, so the use of galvanized sheet in the automotive industry is increasing year by year.

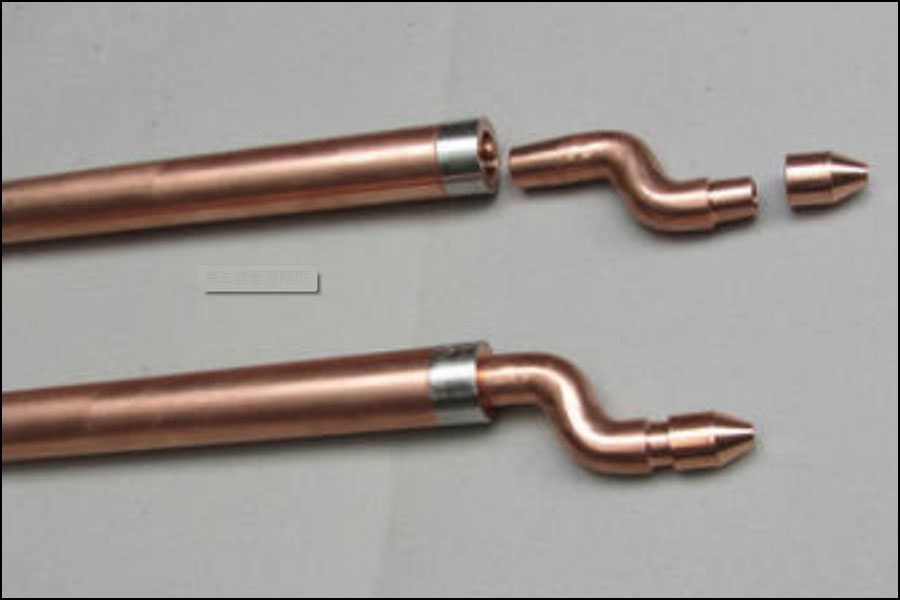

As the welding performance of galvanized steel is significantly worse than that of ordinary steel, problems such as electrode adhesion, false welding of solder joints or too small nugget, and shortened electrode life are often encountered during the welding process, and the state is unstable, which seriously restricts In order to achieve the superior performance of galvanized sheet and the improvement of production efficiency. Wonder Company mainly introduces the characteristics of aluminum oxide copper electrode cap and its application in galvanized sheet welding.

Characteristics of common electrode materials

Electrode is an industrial consumable. Common electrode materials are chromium copper (CuCr), chromium zirconium copper (CuCrZr), aluminum oxide copper (C15760) and beryllium copper (BeCu). Chromium copper is mainly used for welding carbon steel plates and stainless steel plates. Chromium-zirconium copper is mainly used for welding carbon steel plates, stainless steel plates and coated plates; aluminum oxide copper is mainly used for welding galvanized plates, carbon steel plates, stainless steel and aluminum products; beryllium copper is mainly used for welding plate parts that are subject to greater pressure. As well as harder materials, it is also used for some electrode accessories with higher strength requirements, and has good elasticity and thermal conductivity, which is very suitable for making stud welding chucks.

Electrode caps are a must

1. Chromium-zirconium copper (the main medium is copper, and the composition contains 0.25% zirconium and 0.1% chromium) by virtue of its good balance between the four performance indicators of the welding electrode, that is, better electrical conductivity (to ensure the welding process The medium impedance is small, to obtain excellent welding quality), high hardness and strength (to ensure that the electrode cap is not easily deformed under normal working pressure to ensure the quality of the solder joints), and a higher softening temperature (to ensure that the electrode material is high temperature during welding) The performance and life in the working environment) and strong wear resistance (to ensure that the electrode is not easy to wear, which helps to extend the life and reduce costs) and relatively cheap manufacturing costs have become the most common resistance welding electrode materials.

2. Alumina copper is also called dispersion strengthened copper, which belongs to powder metallurgy. The main medium is copper, which contains 0.5% or 1.1% Al2O3. It has the following characteristics:

- The softening temperature is as high as 900℃, and it has excellent high-temperature mechanical properties.

- The hardness exceeds 84HR, the strength reaches 600MPa/n/mm2, the fatigue performance and wear resistance are better than chromium zirconium copper, and the service life is longer.

- The impedance of the welding circuit is small, and the conductivity is high, reaching 80~85IACS%.

- The heat dissipation performance is between tungsten copper and pure copper, about 220~390W/(m·k).

- The cost is high and the scope of application is currently narrow.

Application of Alumina Copper in Automobile Galvanized Sheet

High-temperature mechanical properties are an important indicator for evaluating welding electrode materials. The softening temperature of aluminum oxide copper up to 900 ℃ determines that it becomes the best material for welding galvanized sheets. So why does aluminum oxide copper have such excellent high temperature mechanical properties?

The original alumina copper is dispersedly distributed with alumina particles, the size of which is about 3-12nm, and the particle spacing is about 50-100nm, which has strong stability. Because the volume of alumina particles is small, the volume fraction of the matrix is very small, and the inherent strength and particle spacing can still be maintained at the temperature close to the melting point of copper, so it hardly affects the inherent physical and chemical properties of the copper and aluminum of the matrix, thus creating The above-mentioned various excellent properties of aluminum oxide and copper.

The advantages of aluminum oxide copper electrode caps when used in welding galvanized sheets are as follows:

- 1. Solve the common electrode bonding phenomenon in galvanized sheet welding. There is a zinc layer on the surface of the galvanized sheet and the melting point of zinc is relatively low (melting point is 419°C, boiling point is 907°C), and the zinc layer on the steel surface is the first to melt during spot welding.

- 2. If the material used for the electrode head during resistance welding is chromium copper or chromium zirconium copper, the high temperature generated during welding will cause the molten copper in the electrode material to react with the molten zinc on the surface of the galvanized sheet to produce copper and zinc. The alloy adheres to the surface of the electrode, causing the electrode to bond with the plate.

- 3. Since the softening temperature of aluminum oxide copper is as high as 900°C, which is higher than the temperature between the electrode and the galvanized sheet during resistance welding (about 800°C), it can effectively solve the adhesion phenomenon when welding the galvanized sheet.

- 4. Improve welding stability, ensure the quality of solder joints, and reduce the risk of false welding. When using chromium-copper or chromium-zirconium-copper materials for resistance welding of galvanized sheets, brass is produced. Because the mechanical properties of brass are lower than those of electrode alloys, the diameter of the end face of the electrode cap will increase as the number of solder joints increases. The mushroom-shaped increase in resistance reduces the current density, which affects the quality and performance of the solder joints, and is prone to quality problems such as false soldering and small solder joints.

- 5. Since the aluminum oxide copper electrode cap does not contain chromium and has a high softening temperature, it is not easy to generate copper and zinc compounds when welding galvanized sheets, which can improve welding stability, ensure the quality of solder joints, and greatly reduce the occurrence of unqualified welding. Point of risk.

- 6. According to the data during the development of Wonder and the actual usage of the customer, when the chromium-zirconium copper electrode cap is welded to the galvanized sheet, the frequency of grinding the electrode cap is increased from 300 solder joints when welding ordinary plates to 20 solder joints once. , Leading to the situation that the electrode cap needs to be polished when welding a white body in some stations, and the production efficiency is drastically reduced. In addition, the service life of the electrode cap has been reduced from 6000 solder joints for welding ordinary plates to 550-600 solder joints. Frequent replacement of the electrode cap is necessary, which not only reduces production efficiency, but also increases costs.

- 7. Under the same experimental conditions as above, use aluminum oxide copper electrode caps for experiments. It was found that the grinding frequency of the electrode cap can be maintained between 250 and 300 solder joints, and the life of the electrode cap reaches 2000 solder joints, which is more than three times the life of chromium zirconium copper, while ensuring production efficiency.

- 8. When using aluminum oxide copper electrode caps for welding, the welding sparks are small or no sparks are generated, and the solder joints are beautiful, and there is no blackening or yellowing of the solder joints.