Beryllium copper material has very good processing and forming functions. After heat treatment, its hardness, strength, corrosion resistance and fatigue resistance can be improved. It has excellent electrical and thermal conductivity and is a structural material with excellent general functions. Mainly used as elastic elements and wear-resistant parts. The surface of the parts is surface modified by silver plating, which can advance the welding function of the device and the conductive function of the components.

The composition of beryllium copper alloy contains beryllium, nickel and titanium, which are easily passivated. Even in the atmosphere at room temperature, a fine oxide film invisible to the naked eye will quickly form on the surface. At the same time, beryllium copper parts often have to undergo annealing, quenching aging and other heat treatment processes. Even if vacuum heat treatment is selected, the surface will inevitably undergo different degrees of oxidation. The oxide film on the surface of beryllium copper material mainly consists of CuO, Cu2O, BeO, NiO, Ni2O3, TiO2, etc. The oxide film is fine and solid.

Organic solvent degreasing, chemical degreasing or electrochemical degreasing can be carried out according to conventional methods, and metal cleaning agents can also be used for degreasing to ensure that the surface oil on the parts is completely removed. When the parts are immersed in the water and show a continuous and intact water film, it indicates that the oil stain has been completely removed and clean.

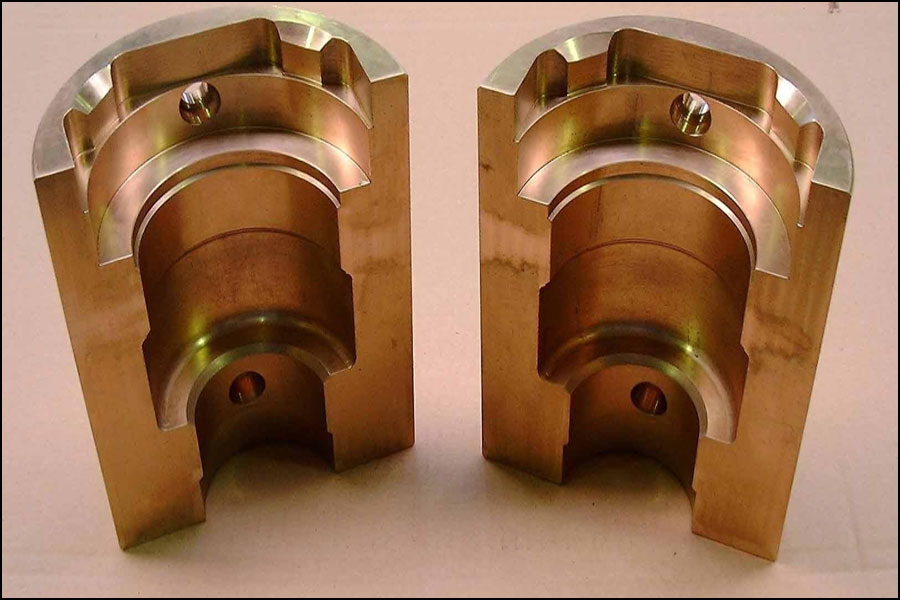

The functions and uses of beryllium copper: high-performance beryllium copper has a hardness of (HRC) between 38 and 43, a density of 8.3g/cm3, and a content of beryllium 1.9%-2.15%. It is widely used in the inner inserts and molds of plastic injection molding molds. Core, die-casting punch, hot runner cooling system, heat conduction nozzle, integral cavity of blow mold, automobile mold, wear plate, etc.

High hardness, wear resistance and resistance: as an insert, it can be used in cooperation with die steel and aluminum to maximize the efficiency of the mold and extend the life of the mold; high thermal conductivity: 2 to 3 times higher than steel , The cooling effect is excellent, can shorten the cycle time of beer molding, excellent heat dissipation effect, effectively reduce product deformation and shortening, control the shortening rate after beer molding, improve standard stability, and advance productivity.