When the metal changes, two changes will occur when exposed to high temperatures, namely instantaneous changes and metallurgical changes.

Instantaneous change vs. metallurgical change

Transient changes are reversible temperature return to normal, metallurgical return to normal changes, usually involving phase changes, are permanent. Examples of phase changes include solution annealing, precipitation hardening, steel quenching, tempering, melting, etc. Creep stress relaxation is based on diffusion and does not involve phase metallurgical change conversion. Most metallurgical changes are a function of time and temperature. Higher temperature increases the reaction rate Arrhenius relationship.

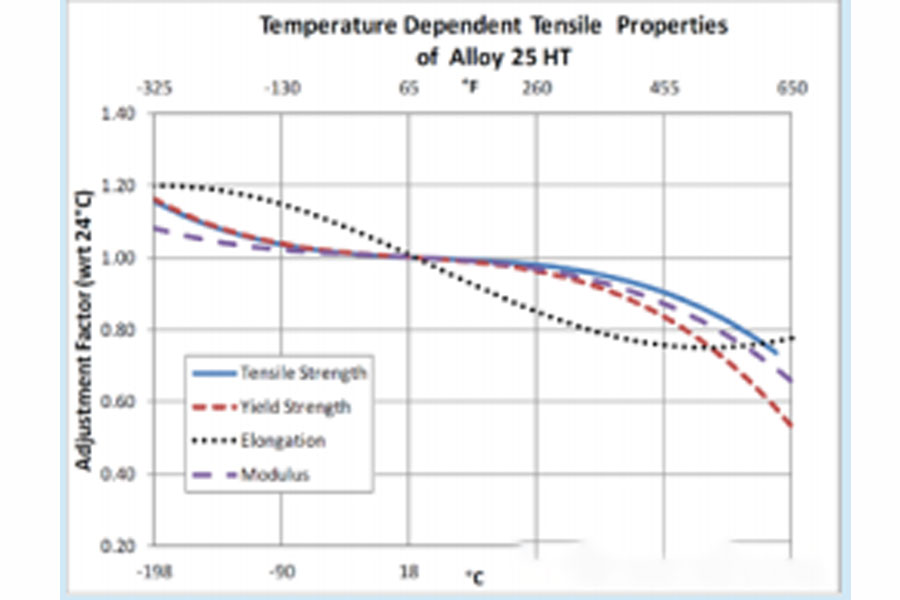

As shown in Figure 1. The change temperature of alloy 25ht instantaneous value material properties.

This graph shows the effect of temperature on the tensile properties of C17200 TH04 copper beryllium. For this test, the sample was heated to the required temperature and the test was performed to keep the sample at that temperature throughout the test. This test is an effective measure only for the effects of instantaneous changes and no metallurgical changes.

Figure 1 shows the transient effect of temperature on the tensile properties of 25ht alloys. The properties list their room temperature value. These curves are non-linear, indicating that the rate of change increases or decreases with temperature. Pay attention to the yield strength, the modulus of elasticity and the tensile strength remain relatively stable. Room temperature gradually begins to decrease as the temperature rises. When the temperature difference increases, the rate of change increases. On the other hand, tensile elongation shows strength and relative modulus of curvature. Relative to. The maximum rate of change at room temperature decreases with temperature changes. The curve also has an obvious inflection point that indicates the minimum ductility that it passes through at certain high temperatures.

Also pay attention to the temperature rise when the room temperature drops in strength, modulus, and elongation. The enhanced strength elongation indicates increased toughness at low temperatures. This is the alloy for most copper, contrary to most steel alloys. While steel alloys become more brittle at low temperatures, copper alloys become harder. While steel alloys become more ductile when elevated, the temperature rises, and copper alloys become more brittle.

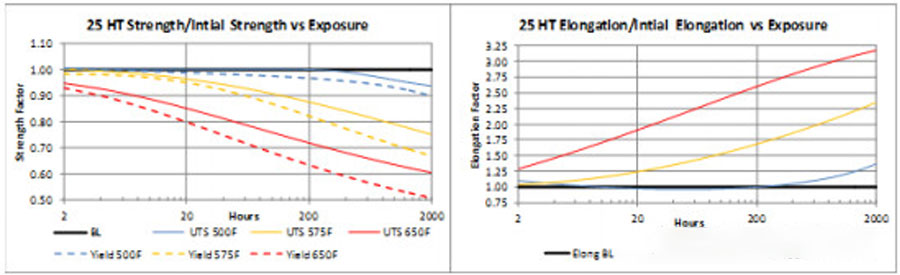

Figure 2. 25 HT alloy performance with temperature and time.

In this test, the tensile sample is heated to the desired temperature and kept for the specified time, and then it is allowed to cool completely to room temperature. Then perform the actual tensile test temperature indoors. This special test only measures the effects of metallurgical changes, not instantaneous changes.

Figure 2 shows the effect of metallurgical changes on the tensile properties of 25ht alloy. The effect of instant changes is eliminated. While Figure 1 only shows the relevant change temperature, Figure 2 must also include the time-influencing factors, just as the metallurgical changes have the same function time and temperature.

Alloy 25 is a precipitation hardening alloy. The precipitation reaction starts at 500°F (260°C). Below this temperature, only transient and diffusion-based properties change. Please note that in these curves, the change is a non-linear function of time and temperature. The fact is that the curve is almost linear on a logarithmic scale and represents the time these changes are exponential functions. It is also noticed that in the early stage, the speed temperature change increases with the increase of the temperature difference, and it is stable. This stabilization occurs when the material is completely expired when the precipitation reaction is over.

These two sets of curves separate the instantaneous and metallurgical changes of the effect. In many applications, these two changes will occur simultaneously, further complicating forecasting. Especially performance at high temperatures when it comes to changes in metallurgy. Even when the high temperature phase transition cannot be produced, the stress can relax. You will need to carefully consider the materials used for any application that requires elevated temperatures to run for a long time. You may need to use finite element analysis to simulate the effects of time and temperature.