The formability of copper alloy strips is usually measured by the R/t ratio (sometimes called the MBR/t ratio). This specifies the minimum recommended internal radius of curvature (R) necessary to form a 90º bend in a strip of thickness (t) without failure. A material with good formability will have a smaller R/t ratio, while a material with poor formability will have a higher R/t ratio. If the R/t ratio is equal to zero, then theoretically, the material will withstand sharp bends (zero radius). For a 90º bend, this means that the two legs of the punch will intersect at a perfect right angle.

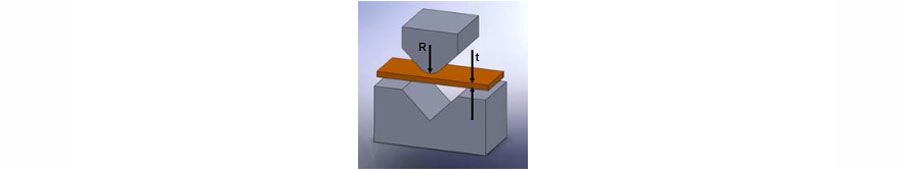

Conventional methods are used to calculate the R/t ratio of a given strip, including V-shaped blocks and W-shaped blocks in guided, semi-oriented or non-oriented tests. In the V-block test, a 90° punch with various radii of curvature is used to press a test piece into a 90° mold (Figure 1). After each test, remove the test piece and check the outer diameter of the elbow for cracks. If there are visible cracks, the material has failed the test. If there are no cracks, use a punch with a smaller radius to retest the material. Repeat this test with smaller and smaller radius punches until failure occurs. This provides us with the smallest material R/t ratio.

Figure 1. 90°V-shaped block test

Figure 2 illustrates several possible results of the bending test. When the punch radius is large enough, the steel strip should be bent smoothly on the inner and outer radius. As the punch radius decreases, the outer radius begins to show orange peel. This is the wrinkle texture on the surface, which looks similar to the orange texture. Orange peel does not necessarily indicate cracking. For a very insufficient bending radius, the sample will show obvious cracks and may even break in half during the bending test. If you are not sure about the crack, you can twist and bend it manually. If cracks appear in the test bend, the reverse bending will cause the sample to break.

Figure 2. Gradually severe bending

There are several factors that determine the degree of bending. The grain size is important. If the bending is carried out without stretching the material, the smaller grains have better formability. If the material is stretched during the bending process, larger grains will provide better formability. Metal tempering (cold work, strain hardening) also affects its bendability. Since ductility is inversely proportional to strength, higher-strength tempers are more difficult to shape than lower-strength tempers. Tempering after annealing will show the best formability, while cold working tempering like springs and springs will require a larger bending radius. Therefore, in addition to strain hardening (cold working, work hardening), alloys that also rely on strengthening mechanisms have advantages because they require less cold work to achieve the same strength as strain hardening alloys.

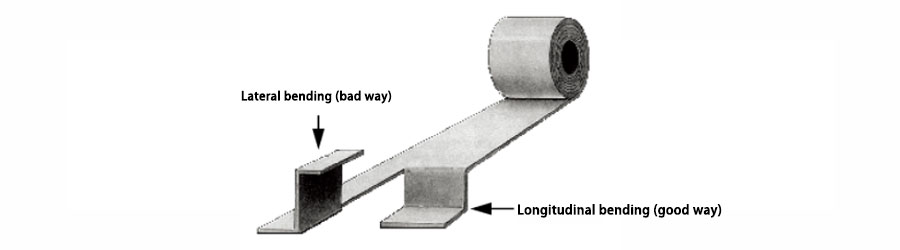

The orientation of the bend relative to the rolling direction of the strip is important. When bending in the longitudinal (good way) direction, ribbon alloys are generally easier to shape than when bending in the lateral (bad way) direction. (Figure 3) Therefore, formability is specified in both the vertical and horizontal directions. This directionality increases as the amount of cold work in the metal increases. This is important because many molds are oriented in the direction of poorly bent parts.

Picture 3. Vertical and horizontal bending directions

Unfortunately, the R/t ratio only indicates the formability of the material. Even if the R/t ratio is satisfied, there is no guarantee that a given bend will not actually break. It is important to remember that even if the ratio is quoted as a constant for a particular alloy and temper, it may actually vary depending on several other factors. A thinner strip will accept a smaller bend radius without cracking, while a thicker strip will require a slightly larger radius. Narrow strips (width less than eight times the thickness) will generally be able to accept smaller radii without failure.

In addition, the 90 V block test is very subjective. It is up to the tester to determine what constitutes a “fault”. For example, will orange peel be considered a failure, or will the test pass until the rupture occurs? Second, the dynamics of the bending test played a role. Higher punching speed or higher punching force will make the material easier to break. Punching speed and force will depend on the operator. In addition, there is very little bending on the stamping die using 90ºV block and punch.

There are several other ways to determine formability. The 180º bending test can also be used, but there are fewer reports. It should be noted that a 180° bend usually requires a larger bend radius than a 90° bend, although not necessarily twice. In some tests, a “W”-shaped bend test is also used, in which 3 bends are put into a ribbon sample.

In short, when choosing a material to be used in an application, it is important not to neglect the formability of the material. Since strength and formability are inversely proportional, it is always best to use the highest strength material that meets the formability requirements.