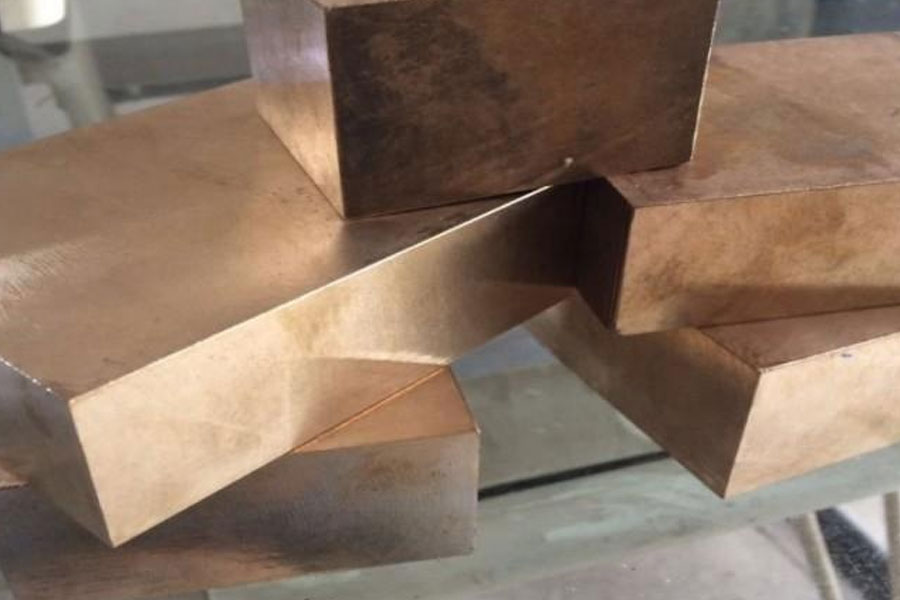

Beryllium copper tape is a precipitation hardening alloy. High-performance copper beryllium strips are mainly used in various working conditions of non-ferrous metal low-pressure and gravity casting molds. Through in-depth research on the causes of failure of the beryllium copper strip mold materials, the internal relationship between the composition and the corrosion resistance of molten metal, the The high-performance beryllium copper belt mold material that combines strength, wear resistance, high temperature resistance, high toughness, and corrosion resistance of molten metal solves the problems of low pressure of domestic non-ferrous metals, easy cracking and easy wear of gravity casting molds.

Beryllium copper has higher corrosion resistance, wear resistance, and no sparks when impacted. Beryllium copper tape is used for medium-speed and heavy-duty bearings, with a high working temperature of 250°C. It has the characteristics of self-aligning, insensitive to deflection, uniform force on the bearing, high bearing capacity, radial load at the same time, and self-lubricating without maintenance.

Beryllium copper tape is a kind of alloy copper with good electrical conductivity. The beryllium copper tape is not easy to generate heat, ensures safety and has strong fatigue resistance. The socket reed of the beryllium copper tape has a hard-wired electrical structure, no rivet connection or no friction contact, which can ensure good contact, good elasticity, and smooth insertion. Beryllium copper belt has excellent machining performance and chip forming performance, which can quickly shorten the processing time of beryllium copper belt parts.

As a master alloy, beryllium copper strip is widely used in copper casting, soldering and other fields, and beryllium copper strip occupies an important place in the development of the national economy.