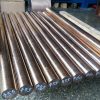

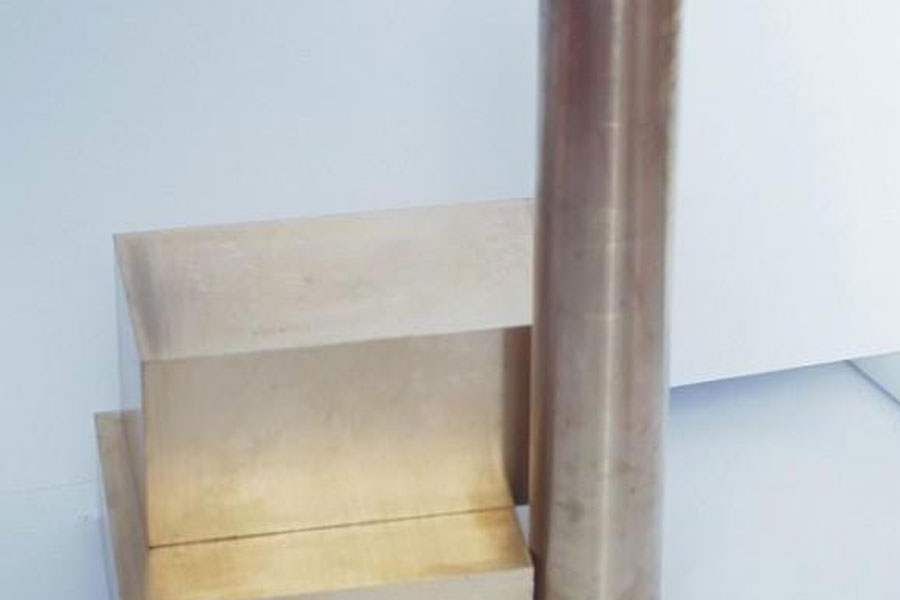

It can be distinguished from the appearance: brass is golden yellow, phosphor copper is brown, beryllium copper is magic white, and red copper is a little purple. The difference in hardness: phosphor bronze has good elasticity and hardness, brass has good toughness, beryllium bronze and red copper are poor in elasticity and toughness. Beryllium copper generally has higher strength. If it is a small size material, you can bend it by hand for comparison; if it is a large size, you can hit the Shore hardness.

Features: beryllium copper has excellent electrical conductivity, thermal conductivity, high hardness, wear resistance, explosion resistance, crack resistance and high softening temperature, fast welding speed, low cost, suitable for electric spark and welding electrodes. It is a choice of materials to replace tungsten copper based on data cost considerations.

High-performance copper beryllium is mainly coiled around the various working conditions of non-ferrous metal low-pressure and gravity casting molds. After in-depth study of the cause of failure of beryllium copper mold materials, the internal relationship between the composition and the corrosion resistance of molten metal, the development of high conductivity (thermal) High-performance beryllium-copper mold materials with strength, wear resistance, high temperature resistance, high toughness, and liquid metal corrosion resistance, which deal with the low pressure of domestic non-ferrous metals, easy cracking and easy wear of gravity casting molds, and significantly improve mold life. , Demoulding speed and casting strength; restraining the adhesion of molten metal slag and corrosion of the mold; improving the appearance quality of the casting; reducing the cost of consumption; making the life of the mold close to the imported level.

It is generally applicable to the inner inserts, cores, die-casting punches, hot runner cooling systems, heat conduction nozzles, integral cavities of blow molds, automobile molds, wear plates, etc. of plastic injection molding molds.