For zinc alloy die castings to be electroplated surface treatment, this link is very important. If the electroplating is not done well, all the work in the early stage will be wasted. Therefore, we must pay attention to the electroplating process of the product. Then the quality of electroplating is affected by those factors. Carbide die casting summarizes the following for you:

- For the selection of raw materials for zinc alloy die-casting parts, regular national standard materials must be selected for product die-casting.

- The design of zinc alloy die-casting parts should be reasonable. The shape of die-casting parts should consider the concealing ability of electroplating, and try to reduce the impervious holes, so that it is not easy to carry the solution in the washing. Cut sharp corners and other parts to make the power lines evenly distributed during electroplating.

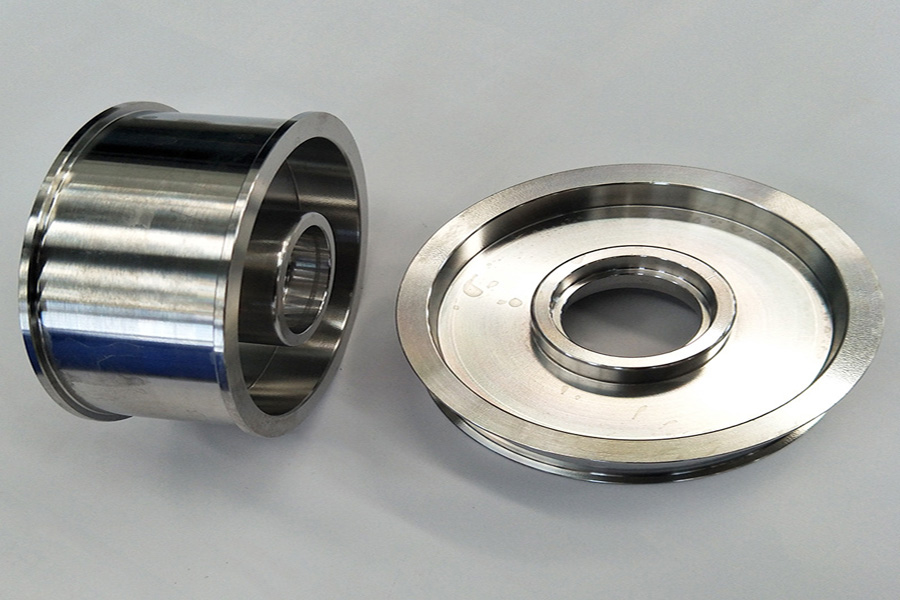

- The die casting and die-casting mold manufacturing design are reasonable, so that the die-casting parts will not suffer from the shortcomings of shrinkage, pinholes and looseness. The above-mentioned shortcomings will directly affect the adhesion of the coating.

- In the production process of zinc alloy die castings, try to reduce the segregation phenomenon. If aluminum segregates in certain parts, aluminum will firstly dissolve during degreasing, which will cause pores and pinholes on the surface of the die-casting parts and cannot be cleaned, resulting in poor bonding strength, resulting in peeling and blistering of the coating.

- Pay attention to the scale during the grinding and polishing process. The fine layer of 0.05-0.1mm formed during the cooling process of the Magnesium die casting is very important for electroplating. The loss of the fine layer should be reduced as much as possible during the grinding and polishing. If this layer is ground and thrown away, What will be revealed will be a porous structure, and no good electroplating layer will be obtained on this layer.

- The copper-nickel-chromium electroplating layer composed of multiple plating types is a negative plating layer relative to the substrate. As long as the soft magnetic mold core materia maintenance is effective, the zinc alloy parts will corrode in the humid air, so it is necessary to ensure that the plating layer is free hole. Otherwise, the corrosion products of the zinc alloy will cause blistering of the coating. Compared with steel parts, the coating should be thicker to be suitable for zinc alloy die castings.

- Residues of die-casting parts in the process of die-casting and die machining should be cleaned as much as possible after processing. Because the residue is a vivid metal, in any process of electroplating, it will react with the solution and damage the plating solution, which will affect the quality of electroplating.

The main factors affecting the electroplating quality of zinc alloy die castings are summarized in the above seven points. We focus on the customization of the die casting industry and have our own surface treatment department. The quality is controllable and the cost is controllable. Welcome to consult if you need it!

Copyright notice: This article comes from https://hotchamberdiecasting.com/