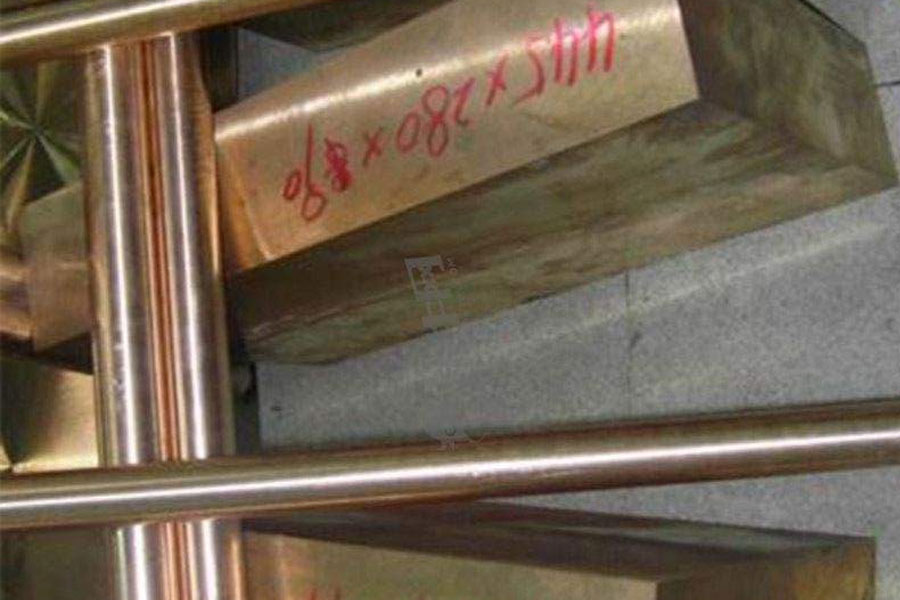

Deformation Process Of High-strength Copper-Beryllium Alloy

Alloy 25 beryllium copper is a high-strength, precipitation hardening alloy. The hardening process greatly improves the strength, hardness and other mechanical properties, although it will cause deformation of the part unless care is taken to prevent it.

Age Hardening

Aging hardening (also known as aging, precipitation hardening, or simple heat treatment) is a phenomenon in which the hardness or strength of the supersaturated solid solution treated by solution treatment is aged at room temperature or above, and the hardness or strength is significantly increased. Hardenable beryllium copper is usually processed or stamped after heat treatment. Hardened beryllium copper is not affected by deformation and provided under aging hardening conditions, without further heat treatment after forming. Age hardening is done after the parts are formed, and the size can still be deformed.

The age hardening of beryllium copper involves the precipitation of a hard beryllium copper alloy matrix in metallurgy. This hard phase has a higher density than the matrix, and the higher temperature where it is formed will cause a slight change in volume during the aging cycle. The volume change is negative, which means that the density will increase. The dimensional change of high-strength beryllium beryllium copper is 0.2%. These values are approximate, because alloy tempering and age hardening time and temperature will produce a little effect on volume change.

Highly conductive beryllium copper alloys (alloys 3 and 10), due to their low content of beryllium, have an almost zero volume change during age hardening. Similarly, the spinodal hard BrushForm®96 and BrushForm®158 copper-nickel-tin alloys do not experience volume changes during spinner decomposition. Distortion is not a problem in these alloys during heat treatment.

If the volume of the entire part changes uniformly during the aging hardening process, the density will increase and the overall shape of the part will not be affected. This size design can include uniform change calculations without major problems. However, if the volume changes unevenly, shape distortion may occur. These factors can cause age uneven hardening in beryllium copper parts.

Temperature changes when large or long parts age are an important problem and possible source of distortion. However, deformation problems are also encountered with small changes in local temperature conditions during stamping or mechanical parts aging.

The most likely reason for the aging and deformation of small parts is uneven residual stress processing, stamping, bending, embossing, straightening, etc. caused by machinery. The flat belt forms a simple bending compression inside the bending and outside in tension.

Since age-hardened beryllium copper is accompanied by volume shrinkage (increase in density), it appears that according to Le Chatelier’s principle, compressive stress will locally promote or strengthen the aging reaction. Accordingly, tensile stress will inhibit the aging process. When a part with bending is age hardening, the aging response (and therefore volume shrinkage) will be the largest within the bending radius, and will pass through the thickness of the strip to the outward bending radius. The occurrence of larger internal volume shrinkage and bending will cause the 90° bending angle to increase during aging.

Flat parts are more prone to aging deformation problems than other shapes. This is because the design features and deformation tendencies are not strengthened

Zoom in by long size. As well as changing angles, aging distortion will cause bending, twisting, buckling and ripples.

Although the aging distortion occurs early in the aging cycle, the heating rate does not affect the deformation. The cooling rate hardens with age and does not affect deformation.

How To Control Part Deformation?

The selection of alloy and tempering, fixing, age hardening conditions, and stamping adjustment can be used to control partial distortion.

A kind of hard alloy beryllium copper alloy is selected to make the aging by the brush to eliminate the aging distortion problem. In stamping or processing, no additional heat treatment is required. The hardened temper can have a range of moldability and strength. The hardened version of beryllium alloy 25 of ground copper is also called alloy 190 and 290.

Most aging deformation problems are stress distribution caused by unevenness. The technical issues used to control these vary greatly depending on the shape of the part. Large parts, including long rods and tubes, can be fixed to prevent metal movement between the plates by fixing the metal to a rigid beam or beam, while other parts may be tightly wrapped in sand. The stamped parts of the small cup can be fixed by nesting, but because of the complexity of the part design, fixing is not a common choice. Thin and flat parts can sometimes be fixed in the design of the plane stiffening feature by including.

The tempering option provides another means of controlling distortion; however, changes in temper also mean a different set of properties after aging. For large deformed diameter rods in cold working and tempering, annealing and tempering sucker rods can be replaced frequently and the effect is very good. In this case, the residual stress caused by cold working is completely eliminated. At other times, the uniformity of residual stress can be selected by increasing tempering. For example, the non-uniformity of residual stresses from bending will be less important to the heavier work in the manufacturing process. Therefore, in order to reduce the aging deformation, the hardest copper beryllium should be selected to meet the forming requirements.

The forming operation itself can promote a more uniform pressure mode. A simple plastic deformation produces a right-angled bending metal that compresses under tension on the outside and inside of the bend. Or, to obtain the same bending structure, the part can be bent through the correct angle initially, and then bent back to the desired angle

The reverse (second) bending operation will force the compression on the outside of the bend (initially the opposite, the internal tension. Will the opposite stress states of two consecutive bends “cancel out” each other to some extent, or reduce Total non-uniformity.

Larger radius bending will reduce stress unevenness. However, as the bending radius increases, stamping after elastic rebound may cause internal and internal residual stress to reverse the mark outside the curve. In this case, the aging distortion will be seen in the opposite direction, with a tighter bending radius. Stamping tools can also be a source of residual stress that causes deformation problems. Boring tool

Or too much die gap can promote deformation of the stamping edge leading to high residual stress, especially in very narrow parts.

If the pressure, or more importantly, the unevenness in the stress cannot be eliminated, the age hardening conditions can be adjusted to reduce distortion. A higher temperature (correspondingly shorter time) for class a age hardening will reduce distortion. High temperature aging will also reduce the peak strength or hardness of the alloy. For example, if the aging temperature of the alloy is 25 raised from the standard 600°F (315°C) to a different temperature of 700°F (370°C), the aging time will be reduced from 2±1 hours to approximately 30±3 minutes . The peak strength is reduced by about 15 ksi (10 kg/mm2), 100 MPa). The 700°F (370°C) level of aging distortion reduction is meaningful, but its magnitude depends on the initial stress state of the part.

Stress relief measures before age hardening may reduce some residual stress, but it is not always effective to eliminate aging deformation. The level of residual stress can be reduced by reducing pressure; however, the inhomogeneity of residual stress persists.

In Conclusion

Distorted parts in the age hardening process of beryllium copper are usually caused by uneven residual stress. The following methods can reduce or eliminate distortion:

- Transform into a mill hardened temper

- Choose the toughest temper shaping needs encountered

- Fixed during age hardening

- Eliminate pressure on parts

- Provide uniform pressure

- Increase the age hardening temperature and temperature decrease time.