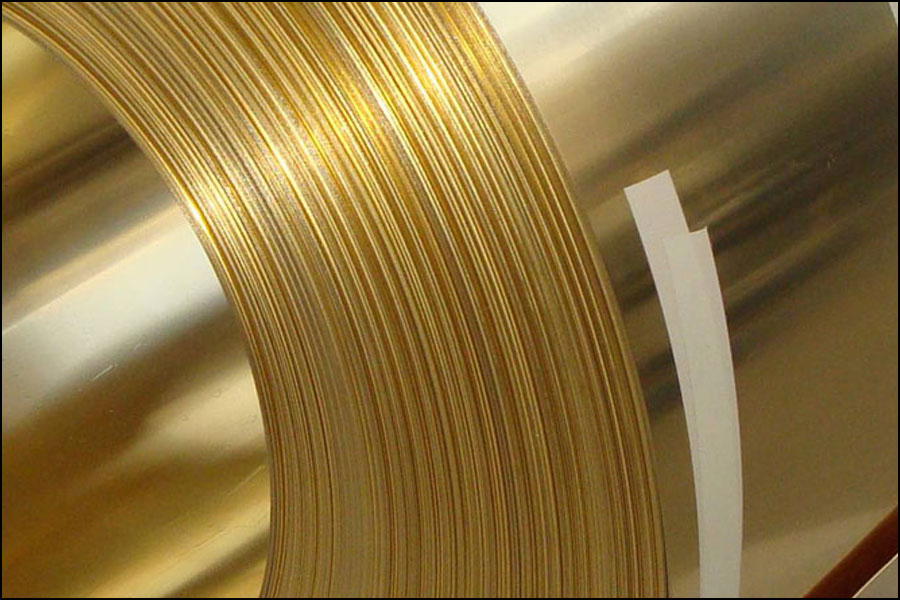

Beryllium Copper Strip

Previous

Next

Wonder copper maintains an inventory of Beryllium Copper round rod and strip.Beryllium copper is a material with good corrosion resistance, rich in ductility before age hardening treatment, and increased in fatigue resistance and conductivity after age hardening treatment.China best manufacturer and supplier of beryllium copper strip, beryllium bronze strip, copper beryllium strip.Contact us to get low price stock beryllium copper quote!

Typical Applcations For C17200 Beryllium Copper Strip

- Electrical Switch and Relay Blades

- Electrical connectors

- Non-Sparking Safety Tools

- Pump Parts

- Bushings/Bearing for

- Aerospace Industry

- Aircraft Engine Parts

- Propellers

- Bolts And Cams.

The complete copper beryllium bar is hauled by a sling, placed on a special cutting table, and then cut by a cutting wheel saw. Each copper block with a length, height and width of 100cm×9.2cm×18.5cm is made, and the weight is about 130kg. Then, the uneven surface of the copper strip is polished and smoothed by the beryllium copper strip surface washing machine, which is beneficial to the flatness and smoothness of the surface of the beryllium copper strip processed in the later stage. At present, because the surface of the beryllium copper strips produced is not ideal, the thickness of 2 mm is removed on both sides. If the beryllium copper strips still have protrusions after washing the surface, they can be polished with a grinding wheel.

Production technology advantage

- All products of the company are made of high-quality new materials, advanced production equipment, and vacuum melting furnaces. The metal materials are smelted under vacuum conditions, which can achieve the effect of high-temperature smelting and avoid oxidation of metal and oxygen in the air. Function, quality is more guaranteed;

- 20MN double-action reverse extruder;

- Equipped with comprehensive testing equipment such as universal testing machine, direct reading spectrometer, etc., to strictly control the quality and inspect layer by layer.

Excellent Properties Of Beryllium Copper Alloy

High Flexibility

High Hardness

High Strength

High Conductivity

High Thermal Conductivity

Good Molding Properties

Good Fatigue Performance

Excellent Corrosion Resistance

No Spark Impact

Chemical Composition

Executive standard:ASTM/GB/T5233-2001/EN12163(%max., unless shown as range or min.)

Numbering

Be

Co+Ni

Cu

Fe

Pb

Si

Al

C17200

1.8-2.0

Co+Ni≥0.2

Margin

0.15

-

0.15

0.15

C17300

1.8-2.0

Co+Ni≥0.2

Margin

0.15

0.2-0.6

0.15

0.15

C17500

0.4-0.7

Co 2.4-2.7

Margin

0.15

-

0.15

0.15

C17510

0.2-0.6

Co≤0.3,Ni 1.4-2.2

Margin

0.15

-

0.15

0.15

QBe2.0

1.8-2.1

Ni 0.2-0.5

Margin

0.15

0.005

0.15

0.15

BeCo1Ni1

0.4-0.7

Co 0.8-1.3,Ni 0.8-1.3

Margin

0.02

-

0.02

0.04

Mechanical properties and conductivity analysis

(AT/TF00)

Numbering

Tensile Strength /MPa

Yield Strength /MPa

Elongation %

Hardness

Conductivity %IACS

C17200

1160-1380

980-1240

3—15

36-42HRC

22-28

C17300

1160-1380

980-1240

3—15

36-42HRC

22-28

C17500

700-920

560-710

10—25

92-100HRB

45-60

C17510

700-920

560-710

10—25

92-100HRB

45-60

QBe2.0

1160-1380

980-1240

3—15

36-42HRC

18-20

BeCo1Ni1

700-920

560-710

10—25

92-100HRB

45-60

Available status

Brush Name

ASTM Name

Description

A

TB00

Solution annealing state (quenched state)

¼H

TD01

Quarter hard

½H

TD02

Half hard (semi-hard)

¾H

TD03

Three-quarters hard

H

TD04

Hard state (full hard)

AT

TF00

Standard aging heat treatment in quenched state

¼HT

TH01

Quarter hard standard aging heat treatment

½HT

TH02

Half-hard standard aging heat treatment

¾HT

TH03

Three-quarters hard standard aging heat treatment

HT

TH04

Hard standard aging heat treatment (a process of comprehensive strengthening of deformation and aging)

Note: In the Brush name:

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).