Wonder Copper FAQs

We have our own factory and more than 35 years of experience.We have also built up this trading company!

Various of payment ways,T/T,LC,WU or Alibaba Insurance!

Sea Freight,Air Freight and others Express all can reach to you!

MOQ is 10 tons,but accept small orders such as samples!

Support OEM and ODM service!

We have our own after-sale department,you can contact us in 24*7 hours.

Wonder Copper Cnc Machining FAQs

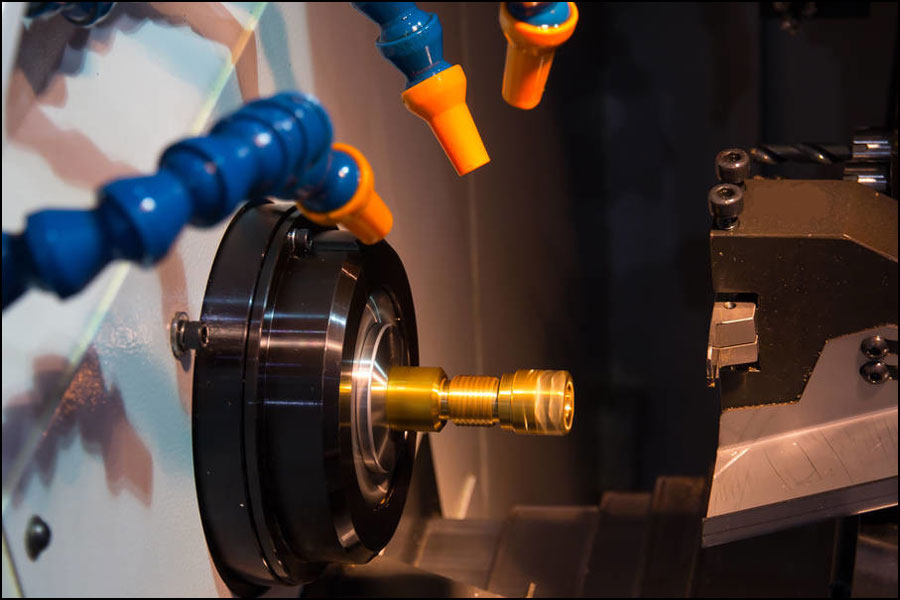

CNC (Consumer Numerical Control) milling and machining is a process in which high tech software creates parts or components for manufacturing. These parts tend to be more accurate and of higher quality than if they were produced using other manufacturing methods. As a result, CNC machined parts are used in industries which rely on absolute accuracy, including aerospace and auto production. The CNC machines used by Wonder Copper & Manufacturing are capable of delivering smaller, delicate components.learn our Turning&Milling case studies.

Many industries benefit from CNC machining, though they are far more necessary in some fields than others. Different CNC machines are capable of different levels of detail during production. For the aerospace/auto/bike/Medical industry, this is essential to their highly specified design plans. There is no room for error when launching a rocket or flying a plan, and CNC machined components from Wonder Factory are made to be as precise as possible.

Capabilities include CNC machining, lathe work, turning, shearing, sawing, forming, punching, milling, drilling, reaming, tapping, routing, broaching and screw machining. Parts such as precision parts, molded parts and components can be machined and fabricated. Reverse engineering, deburring, sanding, buffing, glue laminating, insert installation and assembly services are also available. If you are not sure which method would be best for your parts, just ask our experienced technicians and we will happily assist you.Click Online Quote

Average is difficult to define given the diverse nature of materials and processes utilized at Wonder. We consider ourselves as a “Quick Turn&Milling” operation. Often providing much shorter lead times than typical industrial cutting or machining operations. Additionally giving the fact that we have so many processes in house it allows us to do the entire project (or a large piece of it) saving the customer the time and inefficiencies of utilizing several companies.

We are most experienced at machining beryllium copper alloys.

We are happy to take either approach. We have extensive design and engineering capabilities. We can start with your idea or casual drawing and ultimately produce parts or assemblies to your satisfaction.

Rates vary with process and we employ many processes at Wonder. Basing part or project costs on factory rates assumes all similar factory operate at same level of productivity employing the same level of employees and equipment. Certainly that is not the case. We prefer to provide pricing upon detailed review of your Drawings. This approach is much more valuable to the customer.

Average is difficult to define given the diverse nature of materials and processes utilized at Wonder. We consider ourselves as a “Quick Turn&Milling” operation. Often providing much shorter lead times than typical industrial cutting or machining operations. Additionally giving the fact that we have so many processes in house it allows us to do the entire project (or a large piece of it) saving the customer the time and inefficiencies of utilizing several companies.

Depending on the part complexity and capacity of our company typical lead times range from 2-6 weeks after receipt of order.

If project is used for 2D profile cutting DXF is preferred. If for a machined 3D part stp or parasolid files are preferred.Accept files exported by software such as SOLIDWORKS or CAD etc.,

The majority of our customers are professional parts company. Confidentiality to these organizations is extremely important. All personnel here realize to continue and flourish we must abide by the customers wishes without exception. We have NDA privacy agreements with the majority of our customers(Especially in the aerospace, automotive, medical and other industries). We take confidentiality here very seriously.

ISO 9001:2015 ertified precision CNC machining for OEM parts.PTJ Factory is registered with the D.D.T.C. and is an ITAR certified company

We offer appropriate price&high speed precision turning, milling, and assembly of component parts.

Currently we can handle machined parts up to 60″ x 26″ x 25″. We have plans to expand into larger machining capacity in future

Turning capabilities of up to 14” in diameter.

We have an proven track record of supplying quality parts on-time and at very competitive prices. We fully understand the price pressure put on all of us. We work diligently toward trimming costs everywhere possible on a daily basis. We also understand that our customers need 100% reliable performance from their suppliers. All things considered, we think you will find that Wonder Copper offers some of the best value and dependability in the business.

Learn More About Wonder Copper Inc