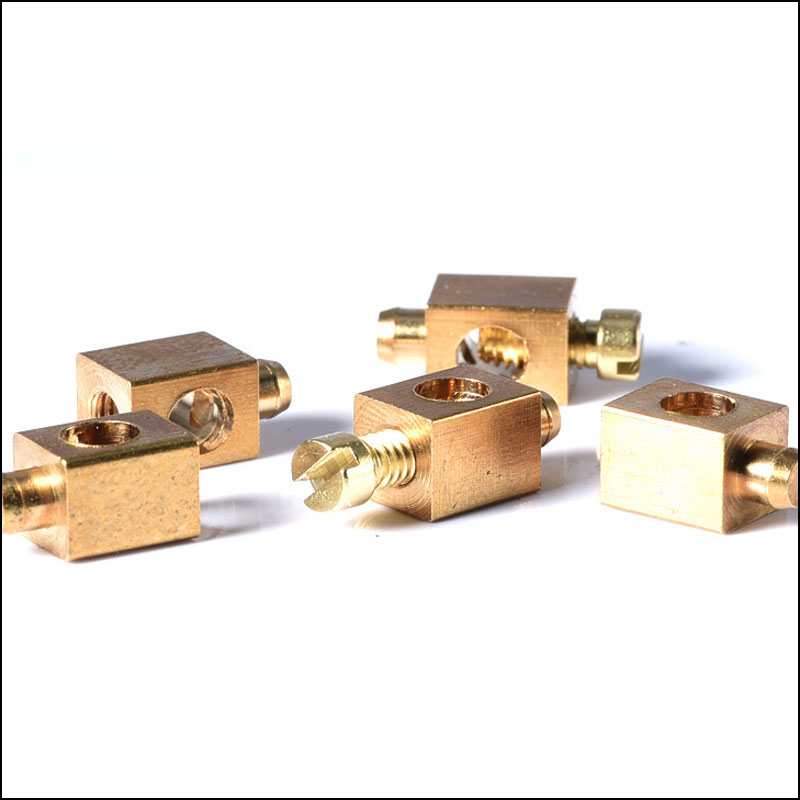

Beryllium Copper Plunger Tips

Previous

Next

Wonder copper are capable of producing beryllium copper plunger tips according to Customer’s drawing and available samples or detailed inquiry.

The plunger tips are made of special copper alloys and used to shoot the fluid aluminium or magnesium into the moulds of horizontal die casting machines, the most commonly copper material can be CoCoBe, CuCoNiBe and CuNiCrSi, etc…With its full suite of Beryllium Copper Plunger Tips Machining Services, Wonder copper can handle all your plunger tips machined parts through reliability and cost savings. Request a quote today!

Plunger Tips Available products

- C17200 (Alloy 25) beryllium copper plunger tips

- C17500 (Alloy 10) beryllium copper plunger tips

- C17510 (Alloy 3) beryllium copper plunger tips

- CuCo1Ni1Be beryllium copper plunger tips

Plunger Tips Typical application

- Aluminum die casting industry

- Plastic Molding industry

Beryllium Copper Plunger tips advantage

- High Strength and higher hardeness

- lower consumption of lubricant

- improved cooling ability

- reduction of casting costs

- longer life of casting chamber/casting capacity

Excellent Properties Of Beryllium Copper Alloy

High Flexibility

High Hardness

High Strength

High Conductivity

High Thermal Conductivity

Good Molding Properties

Good Fatigue Performance

Excellent Corrosion Resistance

No Spark Impact

Chemical Composition

Executive standard:ASTM/GB/T5233-2001/EN12163(%max., unless shown as range or min.)

Numbering

Be

Co+Ni

Cu

Fe

Pb

Si

Al

C17200

1.8-2.0

Co+Ni≥0.2

Margin

0.15

-

0.15

0.15

C17300

1.8-2.0

Co+Ni≥0.2

Margin

0.15

0.2-0.6

0.15

0.15

C17500

0.4-0.7

Co 2.4-2.7

Margin

0.15

-

0.15

0.15

C17510

0.2-0.6

Co≤0.3,Ni 1.4-2.2

Margin

0.15

-

0.15

0.15

QBe2.0

1.8-2.1

Ni 0.2-0.5

Margin

0.15

0.005

0.15

0.15

BeCo1Ni1

0.4-0.7

Co 0.8-1.3,Ni 0.8-1.3

Margin

0.02

-

0.02

0.04

Mechanical properties and conductivity analysis

(AT/TF00)

Numbering

Tensile Strength /MPa

Yield Strength /MPa

Elongation %

Hardness

Conductivity %IACS

C17200

1160-1380

980-1240

3—15

36-42HRC

22-28

C17300

1160-1380

980-1240

3—15

36-42HRC

22-28

C17500

700-920

560-710

10—25

92-100HRB

45-60

C17510

700-920

560-710

10—25

92-100HRB

45-60

QBe2.0

1160-1380

980-1240

3—15

36-42HRC

18-20

BeCo1Ni1

700-920

560-710

10—25

92-100HRB

45-60

Available status

Brush Name

ASTM Name

Description

A

TB00

Solution annealing state (quenched state)

¼H

TD01

Quarter hard

½H

TD02

Half hard (semi-hard)

¾H

TD03

Three-quarters hard

H

TD04

Hard state (full hard)

AT

TF00

Standard aging heat treatment in quenched state

¼HT

TH01

Quarter hard standard aging heat treatment

½HT

TH02

Half-hard standard aging heat treatment

¾HT

TH03

Three-quarters hard standard aging heat treatment

HT

TH04

Hard standard aging heat treatment (a process of comprehensive strengthening of deformation and aging)

Note: In the Brush name:

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).