In the process of hot rolling and heat treatment of domestic beryllium copper alloy, the surface of the slab or strip is oxidized. In order to remove the scale on the surface, pickling is required. The general pickling procedure is: pickling-cold water washing-hot water washing-drying. The operation process of the pickling machine currently selected must also pass this procedure.

The pickling technology of the production workshop has the following requirements: the appearance of beryllium copper alloy materials should be clean, the concentration of useful acid and acid solution should be selected, the pickling time should be short, the use efficiency of acid solution should be high, and pollution prevention methods should be adopted. And pay attention to the protection of the human body, consider the recovery and reuse of waste liquid and products.

When pickling beryllium copper alloys, sulfuric acid or an aqueous solution mixed with nitric acid is the first choice. The reaction process is: the oxide scale is dissolved, or the oxide scale is mechanically peeled off by the gas generated by the chemical reaction (gas bubbles of hydrogen).

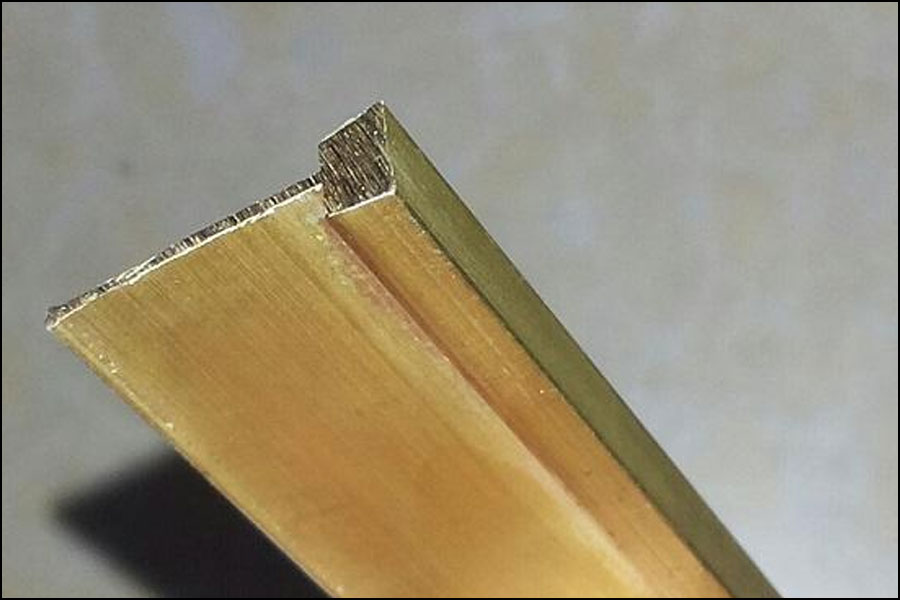

The outer surface of beryllium copper alloy is oxidized. The outermost layer is copper oxide CuO, and the inside of copper oxide is cuprous oxide Cu2O. The dissolution of cuprous oxide in sulfuric acid is very slow. In order to make the surface treatment clean and accelerate the dissolution of cuprous oxide, it is necessary to participate in the sulfuric acid solution with the appropriate oxidizing agent methyl dichromate K2Cr2O7a or nitric acid HNO3. But this will worsen working conditions and reduce the life of the acid tank.

The pickling time of beryllium copper alloy is related to the concentration and temperature of the pickling solution. Generally, the concentration of the pickling solution is 5%-20%, the temperature is 30-60 degrees Celsius, and the time is 5-30 minutes. The details can be adjusted according to the effect of pickling, such as room temperature in summer, steam heating in winter, the upper limit for pure copper and the lower limit for brass. The higher the acid concentration and temperature, the more ferocious the acid mist will be, and the more severe the deterioration of equipment, environment, and working conditions will be. In order to reduce the pollution of smoke, a certain amount of buffer is often used in the pickling solution, and beryllium copper manufacturers try to choose low-temperature pickling.

The disadvantages of beryllium copper alloy pickling include: over pickling, corrosion mottle, residual acid stains, water stains, etc. Over-pickling is mainly composed of high acid concentration, high temperature, and long time. Over-pickling will not only cause corrosion and mottle, but also reduce the appearance quality, and will also consume acid and metal due to overfire. Conversely, if the acid concentration, temperature is too low, and the time is too short, the scale will be incompletely cleaned. Residual acid stains and water stains are primarily clean and unclean, or dry and incomplete. In order to complete the sensitive pickling and improve the appearance quality, new methods of electrolytic pickling and ultrasonic pickling are presented.

In the pickling process, the concentration of the pickling solution will continue to decrease. When the sulfuric acid content of the beryllium copper alloy acid solution is less than 50-100g/ml and the copper content is greater than 8-12g/ml, the new acid solution should be compensated or replaced in time Into a new acid. When making a new acid solution, water must be added before adding acid to ensure safety. Prevent the use of iron in the acid tank to prevent mottle on the surface of the strip. The replaced waste acid solution can be neutralized by ammonia to obtain copper sulfate, copper powder and made into trace element fertilizers, and electrolysis can also be used to obtain regenerated copper and regenerated acid solution. Use a Baume meter to measure the specific gravity of acid when manufacturing beryllium copper alloy acid.