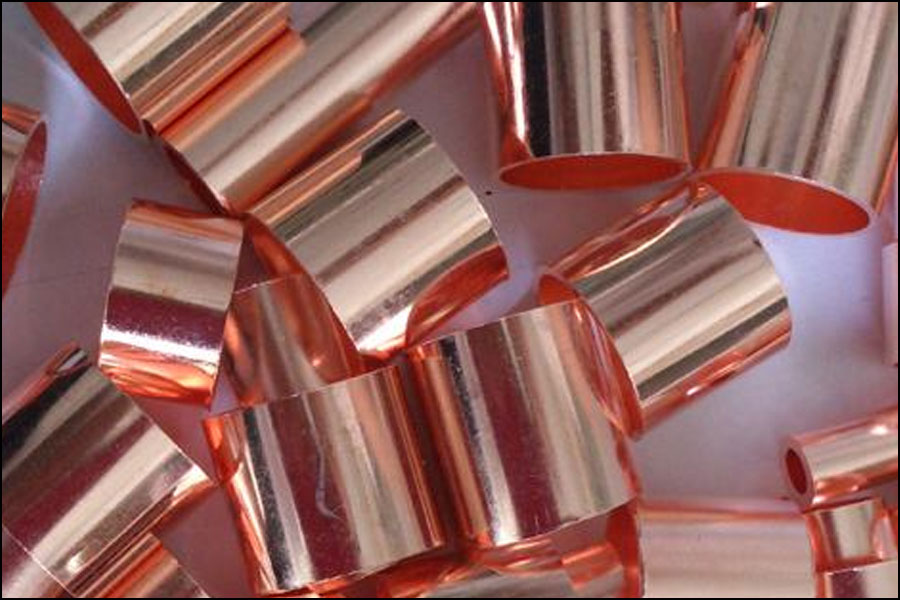

What should I do if the copper material rusts during processing? What should I do if the copper is oxidized? Copper passivation liquid, copper polishing liquid, copper anti-tarnishing agent, copper anti-oxidant, copper sealant, copper maintenance agent, etc. are all commonly used chemicals in the production and processing of copper, which can greatly improve the quality of the product. The editor below will introduce to you the elements that simply cause the copper surface to oxidize, discolor, rust and turn black during the processing process and how to avoid it.

Many process elements in the production and processing of copper and its copper alloy materials will directly or indirectly become the elements of the surface oxidation and discoloration of copper, and their discoloration forms are different, which severely affects the quality of copper parts and subsequent processing. . During production and processing, we must strictly control and manage to eliminate them. NGK beryllium copper lubricating oil, stamping oil, cutting oil and other polluting copper parts: many processes in the processing of copper materials must use process lubricating oil, stamping oil, cutting oil, etc., although the requirements are different depending on the process conditions of different factories. The types of applications (full oil type, emulsion type) and functions are different, and their effects on copper parts are also different, and the size and residual amount of corrosiveness to copper sheets are different. The residues on the surface of the copper parts and the corrosion conditions that simply form a corrosive water film simply lead to the onset of the electrochemical corrosion process, thereby forming oxidative discoloration marks on the surface of the copper parts. To eliminate these effects, in addition to selecting weakly corrosive raw materials, the most useful method is to take effective degreasing and cleaning in time and carry out effective fruit protection.

The effect of residual acid and the water used for cleaning on the corrosion of copper parts: During the processing process, if the copper products have residual acid after pickling, they will quickly corrode and oxidize in the atmosphere with a certain humidity and temperature. , Discoloration, the copper product processing personnel in this process generally understand the reason briefly, but this is also the most common corrosion element. In addition, water quality is very important to the corrosive liquid of copper parts. According to related research reports (causes of spot discoloration on the surface of copper plates and copper strips), the chloride ion impurities in water are the most harmful substances that promote the oxidation and discoloration of copper surfaces, even chlorine The ion concentration below 10ppm will also promote the corrosion of copper parts. This is because the chloride ion has a strong ability to invade and oxidize. When it remains on the surface of the copper part, it will be dry and concentrated at the microscopic defects and form dot-like discoloration. The only way to avoid the above elements is to avoid acid residues in the production process, use water with low chloride ion content and timely passivate the copper parts (you can choose to use copper sealant MS0408 for short-term rust prevention in the central process).

Processing conditions and storage conditions have corrosion factors on the surface of copper parts: directly touching the surface of the copper parts during the processing operation causes fingerprints on the surface of the copper parts, because hand sweat and corrosive media touched by the hands remain on the surface of the copper parts, causing local copper parts Rapid oxidation and discoloration. There is a lot of acid fog in the storage space of copper materials or storage in high temperature and humidity conditions, resulting in rapid and severe oxidation, discoloration and corrosion of the appearance of copper parts. Avoidance: Try not to touch the processed copper products directly with your hands. Store them in dry, low-temperature and acid-free conditions. It is best to passivate and prevent rust.