Titanium copper products can be divided into processing titanium copper and cast satin titanium copper according to the processing technology.

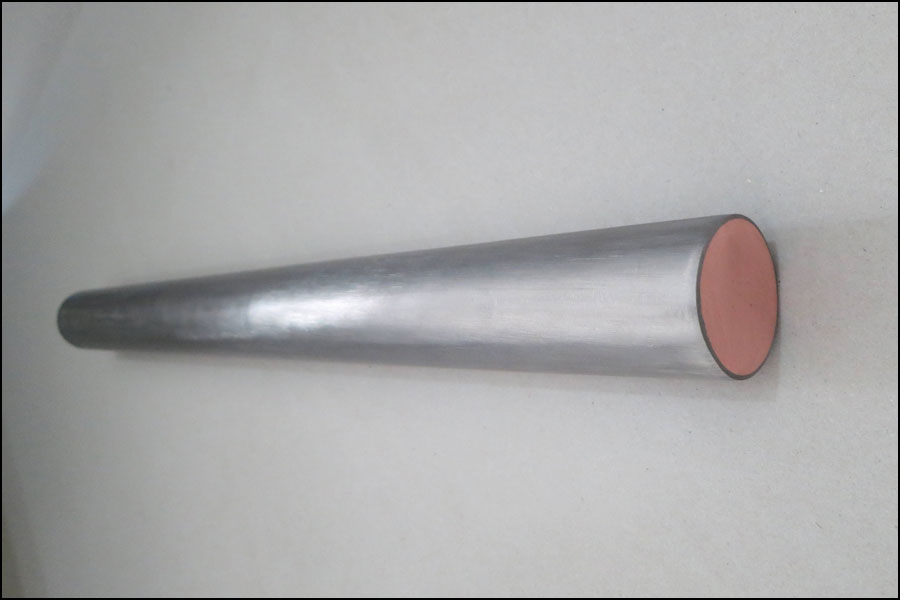

Processing titanium copper includes strips, rods, wires, wires, and tubes. Processing titanium copper has the following characteristics: 1. The strength of processed titanium copper is doubled after heat treatment; 2. The performance of processed titanium copper in different original states is greatly different after heat treatment; 3. The strength of processed titanium copper reaches the level of steel. Electrical and thermal conductivity are much better than steel; 4. Titanium and copper properties of different alloy grades are very different.

At present, the titanium-copper alloys used in the production and processing of materials in various countries are basically divided into two categories. One is the high-strength and high-beryllium titanium copper alloy with a beryllium content of 1.6WT%-2.1WT%. Our country’s grades are C17200, C17000, containing 1.6WT%-2.0WT% Be, and nominal Co content is 0.25WT%. The second type is a high-conductivity low-beryllium titanium copper alloy with a beryllium content of 0.15-0.7%. my country’s brands are C17500 and C17510, with a nominal Co content of 2.5WT% or 2WT% Ni. The recently studied C17400 has a low beryllium content. 0.4WT% or less, its cobalt content is 0.6WT% or less.

Cast and wrought titanium copper can also be divided into two types: high-strength type and high-conductivity type. The grades of high-strength cast beryllium alloys in my country are C82400, C82500, and C82600. C82800 contains 1.6WT%-2.85WT%Be, nominal Co content is 0.5WT%, and a small amount of Si is added. Adding a small amount of Ti to the ingot or increasing the nominal Co content to 1WT% can refine the crystal grain of the cast product. The grades of high-conductivity casting titanium-copper alloys in my country are C82000, C82100, C82200, and the beryllium content is below 0.8WT%.

As far as the current situation is concerned, high beryllium copper is compared with low beryllium copper. Low beryllium copper has excellent electrical conductivity but is not as good as high beryllium copper in mechanical properties. High beryllium copper has better mechanical properties, but its conductivity is not as good as low beryllium copper. The purpose of our heat treatment of titanium and copper is to make it have good mechanical properties and electrical conductivity at the same time to realize the integration of structure and function.