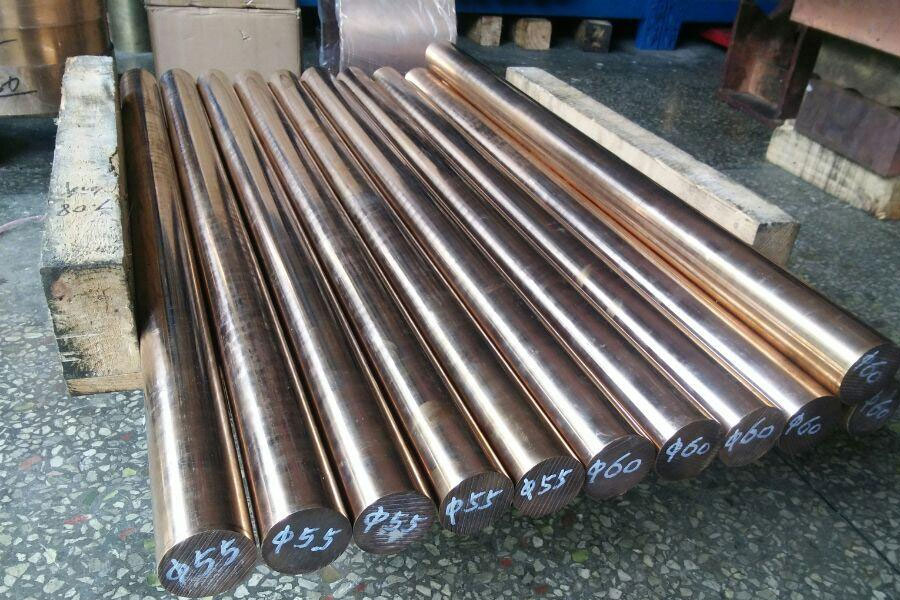

C17200 beryllium copper strip can be used for electrical and mechanical materials, which is higher than general copper alloy products. C17200 beryllium copper belt occupies an agreed position in our lives. C17200 beryllium copper strip is higher than general copper alloy products. No sparks occur during impact. Used for medium-speed and heavy-duty bearings, working at a high temperature of 250°C. It has the characteristics of self-aligning, insensitive to deflection, uniform force on the bearing, high bearing capacity, radial load at the same time, and self-lubricating without maintenance.

The electrical characteristics of C17200 beryllium copper tape provide a shielding effect in the frequency range. At the same time, its mechanical characteristics have a high deviation range, and its long life will not be compressed. C17200 beryllium copper tape shrapnel provides large elasticity and fatigue resistance. Moreover, it has excellent electrical conductivity and a variety of plating options. C17200 beryllium copper has a very high life cycle and conforms to the difference of large gaps, making it an attenuated material.

In order to improve the performance of ordinary C17200 beryllium copper tape, other elements such as aluminum, nickel, manganese, tin, silicon, lead, etc. are often added. C17200 beryllium copper tape has the strength, hardness and corrosion resistance, but it reduces the plasticity, so it is suitable for marine vessel condenser and other corrosion-resistant parts. C17200 beryllium copper tape has the strength and corrosion resistance to seawater, so it is called naval brass, used for ship thermal equipment and propellers. Lead can improve the cutting performance of C17200 beryllium copper strip; this kind of free-cutting C17200 beryllium copper strip is often used as watch parts. C17200 beryllium copper strip castings are often used to make valves and pipe fittings.