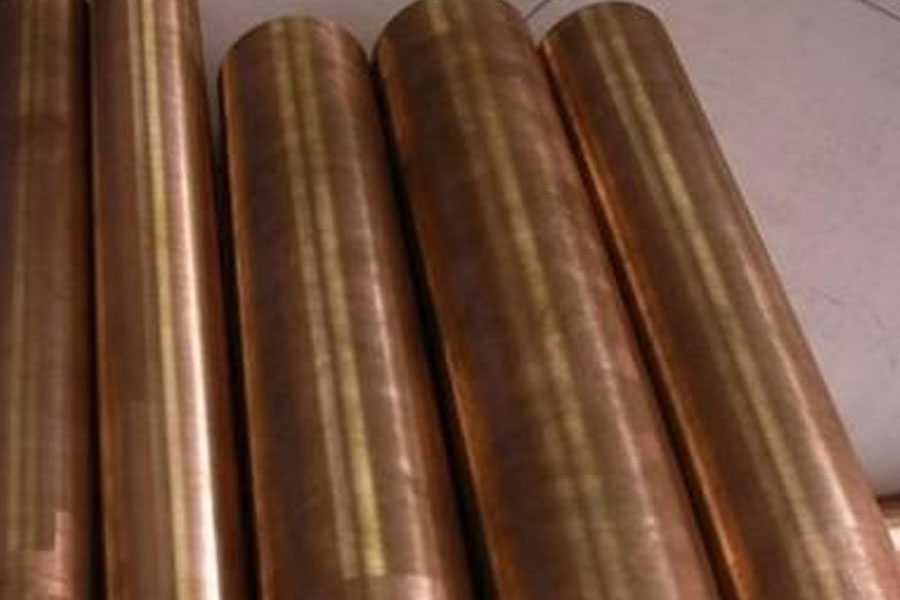

Beryllium copper rods are used in the atmosphere, sea water, fresh water and steam for steam boilers and marine ship parts. Phosphorus-containing beryllium copper has mechanical functions and can be used as grinding parts and elastic parts of high-precision machine tools. Lead-containing beryllium copper rods are often used as grinding parts and sliding bearings. Zinc-containing beryllium copper rods can be used as high-airtight castings.

The beryllium copper rod used for pressure processing beryllium content The beryllium content of the cast beryllium copper rod. Beryllium copper rod is a non-ferrous metal alloy with a small casting shortening rate. It can be used to produce castings with messy shapes, clear generalizations and low air tightness requirements.

Because more cobalt or nickel is added to the beryllium copper rod alloy, the dispersion strengthening particles are mostly intermetallic compounds formed by cobalt or nickel and beryllium. In order to increase the strength of the alloy, a certain degree of cold working is often performed on the alloy after solution heat treatment and before aging heat treatment, in order to achieve a comprehensive strengthening effect of cold work hardening and age hardening. Solution heat treatment should generally be carried out by the alloy manufacturer.

The working environment must have a directional exhaust device. Cutting, polishing and other processes must be carried out in a wet state with coolant. The standard is: regular air sampling is carried out for the operation workshop of beryllium copper rod products and its surrounding environment.

Beryllium copper rod alloy literally means a composite material of two metals, so it has more comprehensive advantages, such as the beryllium copper rod exemplified today, which is the “elasticity” of copper alloys and has high electrical conductivity. Advantages, wear resistance, corrosion resistance, excellent casting performance, so the scope of application, including explosion-proof tools, wear parts such as cams, gears, worm gears, bearings, etc.