Latest Posts

What are beryllium copper and beryllium bronze tubes? 1. Beryllium copper is a copper alloy with beryllium as the main alloying element, also known as ...

The composition of the shielded computer room The shielded machine room is composed of shielded shell, shielded door, power filter, telephone filter, signal ...

The base angle of the mold seems to be a very simple problem, but even the brothers who are now too experienced in mold design to work hard, may have had large ...

With the rapid development of science and technology and the electronics industry, various digital and high-frequency electronic and electrical equipment ...

In more and more engineering applications, materials need to work in a magnetic field. The key requirement of this kind of operation is that the interference ...

At the moment when the mobile phone industry is looking for larger and larger screens, the folding form has become a new direction for smart phones, and the ...

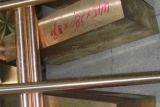

Deformation Process Of High-strength Copper-Beryllium Alloy Alloy 25 beryllium copper is a high-strength, precipitation hardening alloy. The hardening process ...

Nowadays, more and more beryllium copper mold materials are used in plastic mold manufacturing, and there is an upward trend! Why? Characteristics of ...

What is a beryllium copper module? What are the characteristics of a beryllium copper module? Beryllium copper module introduction The beryllium copper ...

With the improvement of people's living standards, more and more people start to buy cars, but a series of problems such as energy consumption, resource ...

KOVAR alloy is an iron-nickel-cobalt alloy with a density of 8.36 g / cm3 and a coefficient of linear expansion equal to that of glass and ceramics with a ...

Rare earth elements (REEs) are a group of metals for short, containing 17 different elements: 15 lanthanides: lanthanum (La), cerium (Ce), praseodymium (Pr), ...

Urea grade stainless steel is a kind of austenitic stainless steel specialized for use in the urea industry. Derivatives such as CO2, NH3, NH2COONH4, (NH2)2CO ...

Drill bits are cutting tools with a circular cross section that create holes in alloy materials. Commonly used drill bits mainly include spiral bits, flat ...